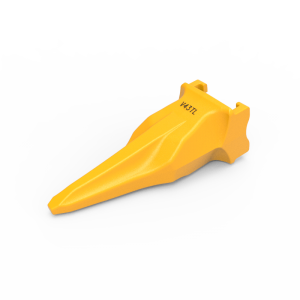

V39SYL ESCO Super V Series General Skid & Excavator Digging Bucket Tooth

Specification

Part No.: V39SYL/V39 SYL/V39-SYL

Weight: 9.6KG

Brand: ESCO

Series: Super-V

Material: High Standard Alloy Steel

Process: Investment Casting/Lost Wax Casting/Sand Casting/Forging

Tensile Strength: ≥1400RM-N/MM²

Shock: ≥20J

Hardness: 48-52HRC

Color: Yellow,Red,Black,Green or Customer's Request

Logo: Customer's Request

Package: Plywood Cases

Certification: ISO9001:2008

Delivery Time: 30-40 days for one container

Payment: T/T or can be negotiated

Place of Origin: Zhejiang,China(Mainland)

Product Description

V39SYL ESCO Super V Series General Skid & Excavator Digging Bucket Tooth,Super V Series Tooth System,Digging Dirt Bucket Tooth,ESCO Conical Top Pinned Tooth System,Super V Tooth Point,Trencher Bucket Chisel Tooth,Blade Bucket Teeth For Excavator Loader,G.E.T. Wear Parts Spare Parts China Supplier

ESCO style Super V series bucket tooth, takes a V39 pin. All ESCO G.E.T. parts are produced to the highest industry standard to ensure our customers' demands for products .

We have standard types and customized products as per customers' requests.

All ESCO G.E.T. parts are produced to the highest industry standard to ensure our customers receive optimum life from our spare parts.

V39SYL ESCO Super V Series General Skid & Excavator Digging Bucket Tooth,Super V Series Tooth System,Digging Dirt Bucket Tooth,ESCO Conical Top Pinned Tooth System,Super V Tooth Point,Trencher Bucket Chisel Tooth,Blade Bucket Teeth For Excavator Loader,G.E.T. Wear Parts Spare Parts China Supplier

ESCO style Super V series bucket tooth, with a V39 pin.

To ensure our customers' product demands, all ESCO G.E.T. parts are produced to the highest industry standard.

We have standard products as well as customized products based on customer requests.

To ensure that our customers get the most out of our spare parts, all ESCO G.E.T. parts are manufactured to the highest industry standards.

As a professional G.E.T. supplier, we have a complete range of wear spare parts for bucket teeth, adapters, cutting edge, protectors, shanks and pins& retainers, bolts&nuts to match .

Direct replacement parts for leading brands(such as Caterpillar, Doosan, Komatsu, Hitachi, Volvo,JCB etc) are provided and used for both construction sector and mining sector.

All European and American Markets are our main markets, nearly 80%-90% of our old customers are from these markets too . We have much experience in our goal markets, trust can meet your request and provide you better service.

Welcome to your soon inquiries !

Hot-Selling Products

|

Brand |

Series |

Part No. |

KG |

|

ESCO |

Super-V |

V13SYL |

0.8 |

|

ESCO |

Super-V |

V17SYL |

1.2 |

|

ESCO |

Super-V |

V19SYL |

2.4 |

|

ESCO |

Super-V |

V23SYL |

3.1 |

|

ESCO |

Super-V |

V27SYL |

5.2 |

|

ESCO |

Super-V |

V29SYL |

4.8 |

|

ESCO |

Super-V |

V33SYL |

6.7 |

|

ESCO |

Super-V |

V37SYL |

9.7 |

|

ESCO |

Super-V |

V39SYL |

9.6 |

|

ESCO |

Super-V |

V43SYL |

12.9 |

|

ESCO |

Super-V |

V51SYL |

16 |

|

ESCO |

Super-V |

V61SYL |

25 |

|

ESCO |

Super-V |

V81SYL |

75 |

Inspection

production

live show

Frequently Asked Questions

Q: How to make sure the teeth can fit other brands well?

A: All of our bucket teeth and adapters can fit the OEM well, also when we make the design we are double check the fitment with BYG bucket tooth and NBLF bucket tooth which is very popular brand on the market.

Q: Will you change the design from different orders?

A: No, we never change the design! We know many customers are very strick on the design and fitment, so each of the tooth we have the part number and mould number, that will make sure you order the same bucket teeth and adapters.

Q: When should be the bucket adapters replaced?

A: Our adapter hardness is HRC40-45, with very strick heat treatment process to make sure is hard and very strength, so after change the bucket teeth 7-10 times the end user have to replace the adapters.

Q: How to make sure that your G.E.T can last long time compare with other brands?

A: All of our parts produced by lost-wax casting only, no any sand casting or forging, with very strick heat treatment process, inner hardness 48 HRC and outer 50 HRC.

Q: Our warranty?

A: Any break, FOC! 100% sure all of our bucket teeth and adapter can fit each other well, no any not fitted!