Company Advantage:

Ningbo Yinzhou Join Machinery Co.Ltd is located in Ningbo Zhejiang, which is famous for casting in China. Our company has been founded since 2006 and become one of the best suppliers of G.E.T spare parts in China with great experience,in the production process and technical strength are absolutely guaranteed . We are Joint Venture of three firms with Ningbo Yinzhou Join Machinery Co.Ltd & Ningbo Qiuzhi Machinery Co.Ltd & Ningbo Huanan Casting Co.Ltd. We have been engaged in the European bucket tooth & adapter & cutting edge & protector & side cutter & lip shround & heel shround for G.E.T spare parts market for over 16 years, and keep improving on quality and the changing European market & customers needs.

Our products have a wide range of various major world well-known brands, not only including the popular products for the market needs, but also relative unpopular special products . We main provide various kinds of excavator bucket teeth replacements of famous brands such as Caterpillar (including J series, K serious, A series,Lip Shround, Side Cutter, Heel Shround,Protector...),Volvo,ESCO(Super V series),Komatsu(Kmax tooth,Side Cutter,Ripper Tooth..),Doosan,Hyundai,Bofors,MTG,JCB,Uniz Series,Liebherr,John Deere, Combi .... We are very pleased to serve for the needs of customers and products can be also customized as per drawings or samples .

We have manufactured and distributed a complete set of parts like bucket teeth & adapters, cutting edges, pins & retainers,bolts & nuts to match for earth moving machines . Our manufactured G.E.T parts are suitable for most kinds of construction and mining machines, and bucket teeth & adapters in different casting processes from 0.1KG to 150KG can all be provided.

We have a professional sales team,especially for our sales manager has a professional understanding and experience and been engaged in the industry of G.E.T spare parts for over 16 years, ever served many European companies such as METALLURGICA VALCHIESE(MV),ESTI,VEROTOOL(VR),ETE,TRASTEEL,ITR....

Our products have been mainly exported to all European and American markets,mainly for engineering and mining . Our quality for teeth & adapters is the first importance to guarantee. If you have interest in any of our products or would like to know more about our products, please do not hesitate to contact us ! We are looking forward to establishing successful business relationships with all customers in the near future .

Welcome your kind inquiries !

Service Advantage:

We have a complete team for pre-sale and after-sale, all emails and inquiries will be answered within 24 hours, WhatsApp is always online and no potential sales opportunities are missed .

All orders will be shipped within the delivery time required by the orders . If there are special reasons for delayed orders, we will communicate with the customers two weeks in advance, but absolutely not appear 3-4 months without delivery .If there is any problem after sale, we will solve in the shortest time and give the results to customers . Free replacements can be provided if any quality problems .

Every weekly meeting with our whole team cooperation is assured , to ensure every order’s punctual delivery and improvement . We have a well-established system that can ensure all orders to go smoothly and our customers satisfied .

Our drawings of all the products are available and can be provided to the customers .Every year we will visit customers in Europe for deeper communication and mutual understanding . To provide customers with the best quality service, we are creating the highest cost performance of bucket tooth & adapter and help customers to success is our consistent objective.

Furthermore, we are committed to providing excellent customer service and support. We understand that our customers rely on their equipment to get the job done, which is why we ensure that our products are delivered within requested delivery time. Our team is waiting at any time for offering assistance to help our customers find the correct bucket teeth and adapters for their specific requirements.

At our service, we are dedicated to providing customers with top-quality, reliable products that are designed to meet their needs and their expectations. By choosing us as your supplier, you can surely have confidence in the durability, compatibility, and performance of our bucket teeth and adapters.

Welcome your inquiries , trust our products and service must be satisfactory to you , sincerely hope you could give an opportunity to recognize our products !

Technical Advantage:

Teeth & adapters & cutting edges are key components of the excavator bucket assembly. These components are subject to extreme forces, wear and impact during excavation. Therefore, strict technical quality control must be maintained to ensure that these parts meet the required standards of durability, strength and performance.Ensuring technical quality control of these G.E.T components is critical to the smooth operation and longevity of the excavators & bulldozers & loaders & scrapers & motor graders...

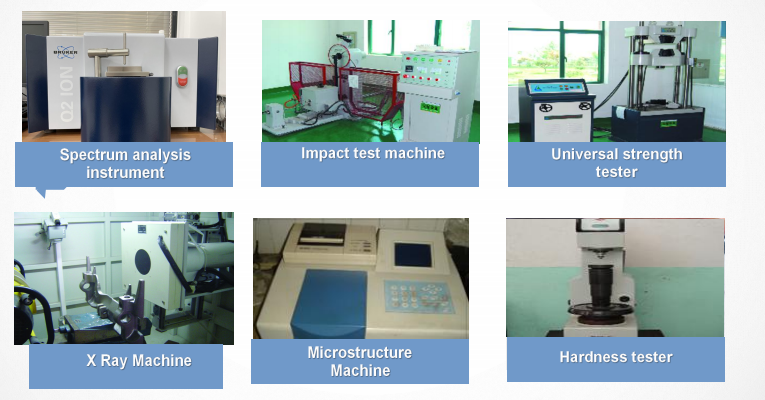

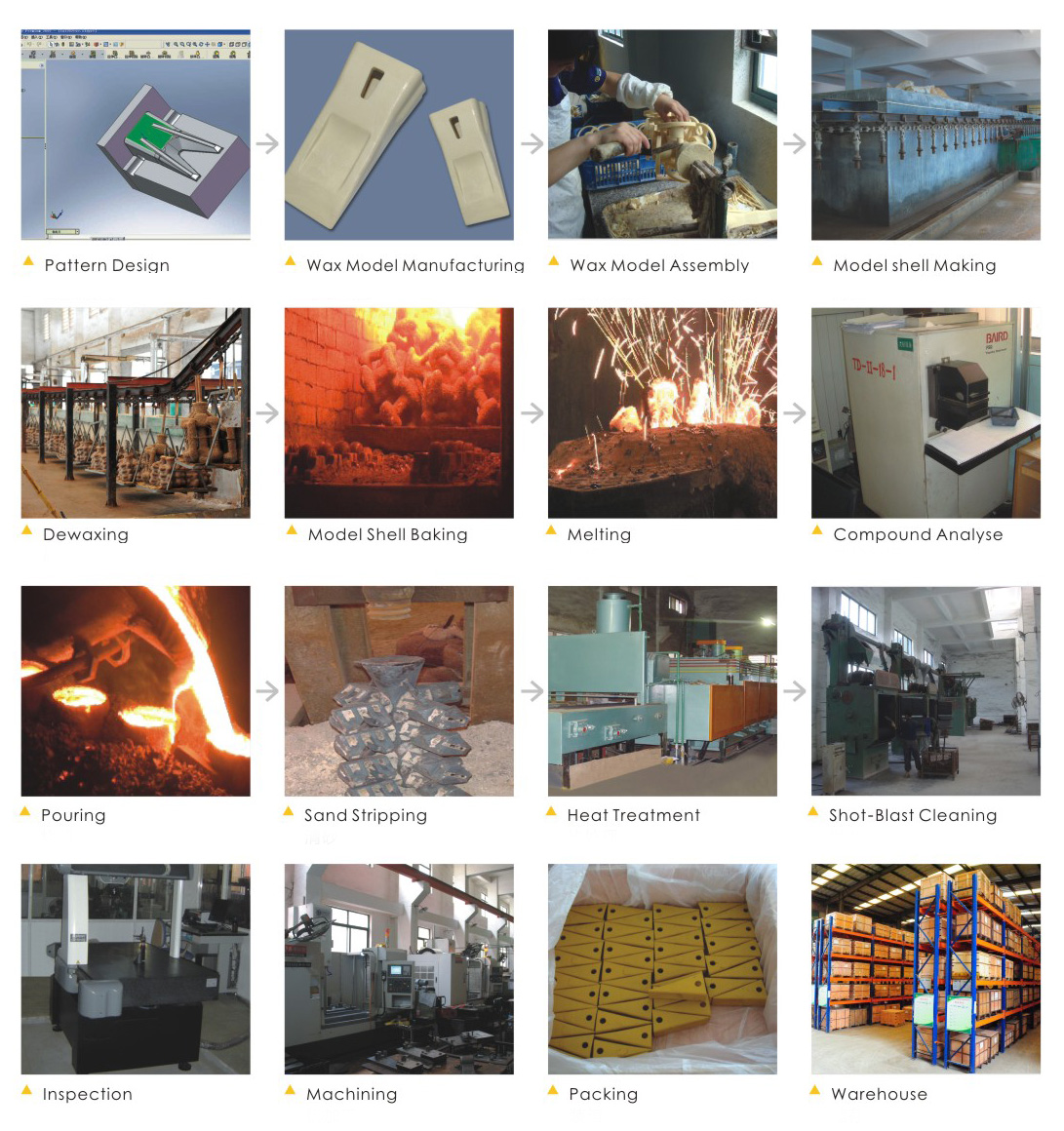

Firstly, the components must come from a reputable manufacturer or supplier who has a good reputation of supplying high-quality products. Before making a purchase, it is important to conduct thorough research and seek advice from industry experts to ensure the supplier has a solid reputation for producing reliable and durable excavator parts. The whole process is controlled strictly from Pattern Design-Wax Model Manufacturing-Wax Model Assembly-Model Shell Making-Dewaxing-Model Shell Baking-Melting-Compound Analyse-Pouring-Sand Stripping-Heat Treatment-Shot Blast Cleaning-Inspection-Machining-Packing-Warehouse, with using many profession inspection machines like Spectrum analysis instrument & impact test machine & Universal strength tester & X ray machine & Microstructure machine & Hardness tester & Hinged arm CMM &CMM & Height indicator & Roughness tester & MPI & UT & Checking fixture .

Once components are obtained, strict quality control processes must be implemented at all stages of production and post-production. This includes meticulous inspection of raw materials, precision machining processes, heat treatment procedures and surface coating applications. In addition, it is critical to conduct comprehensive dimensional inspections, material hardness testing, and metallurgical analysis to verify component integrity and performance.

In addition, regular quality audits and performance testing should be conducted to evaluate the wear resistance, impact strength and overall functionality of bucket teeth, adapters, cutting edges, protectors, lip shround and heel shround. This will help identify any deviations from specified standards and enable timely corrective measures to be taken.

We attach great importance to the quality, and quality control is the core of our company . We have a complete strict QC team from raw material to finished products with using professional mechanical equipment and a perfect quality inspection process .

As a main manufacturer of G.E.T spare parts ,we offer a wide range of spare parts of bucket teeth & adapters, blades,protectors, side cutters,heel shround,lip shround, pins & retainers, bolts & nuts to match, such as brand Caterpillar (including J series, K serious, A series,Lip Shround, Side Cutter, Heel Shround,Protector...),Volvo,ESCO(Super V series),Komatsu(Kmax tooth,Side Cutter,Ripper Tooth..),Doosan,Hyundai,Bofors,MTG,JCB,Uniz Series,Liebherr,John Deere, Combi etc.

Direct replacement parts for leading brands can be provided and used for excavators,loaders,bulldozers,graders,scarifies,both in the construction and mining sectors.

From design-mould-sample-mass production process control, every step of production will be carefully checked to ensure good performance and appearance . Different products use different materials such as Z1/Z11 & Z2/Z12 &Z3/Z13/A9,Z4/Z14/Z10 and heat treatment processes to ensure the best cost value ,With the use of high-quality raw materials, our products have high abrasive resistance, performance, and durability .

All the finished products will be fully inspected again before delivery, so most of the major customers are zero complaints .Our products quality control is very stable, but free replacements can be provided if there are any quality problems .

Good quality is basic and most important belief to us , so we take seriously to the good & steady quality for bucket teeth & adapters & cutter side& protector & heel shround & lip shround & cutting edge and so on .

We have standard types as well as customized products to meet the needs of our customers. Investing good quality excavator parts for bucket tooth & adapters will ultimately bring long-term savings and operational efficiencies .

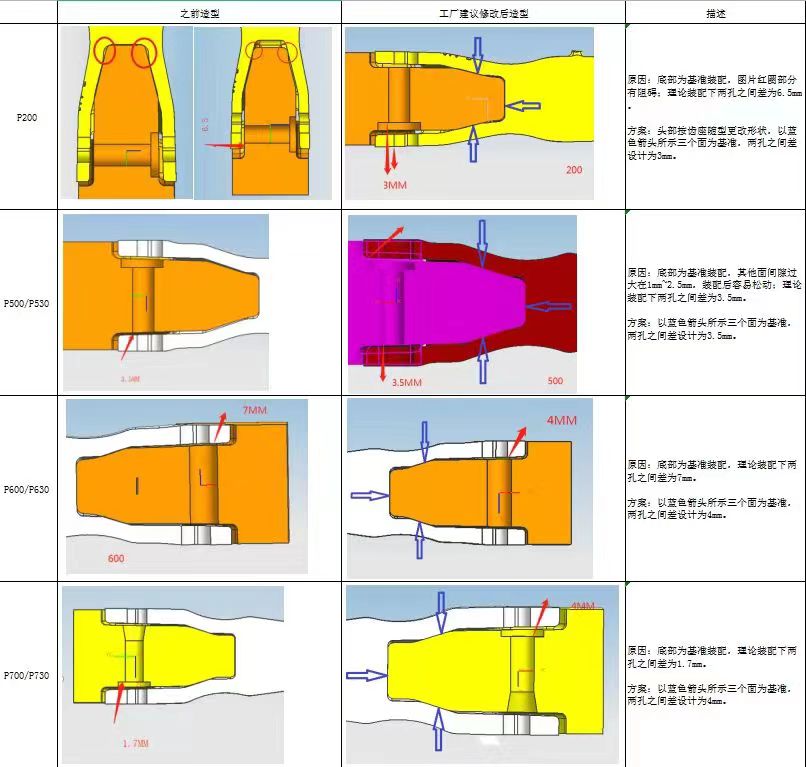

In the European market, we focus on how to make the products more wear-resistant

From the beginning of the designing, so as to improve the cost performance of the products, instead of blindly reducing the weight and thus reducing the price and lead to various quality problems when using the finished products.

Development Advantage:

Bucket teeth & adapters play an important role in the construction and mining industry, and their development has changed dramatically over time . Form humble origins in ancient civilizations to today’s modern innovations, the evolution of bucket teeth has played a vital role in increasing the efficiency and durability of heavy machinery .

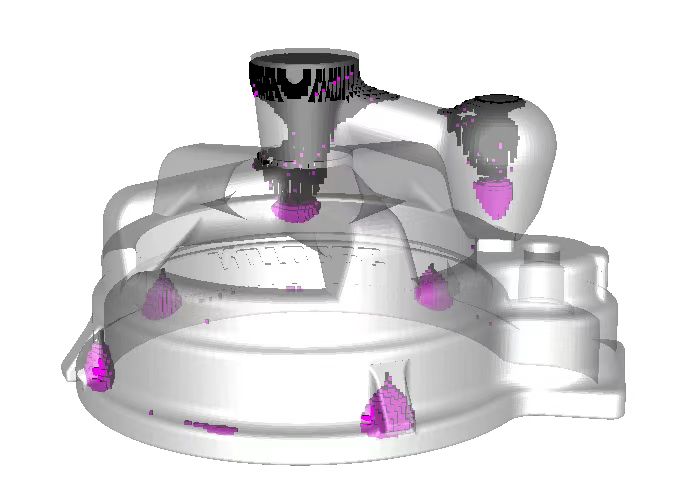

Fast forward to today, the development of bucket teeth has reached a new pinnacle of innovation. With the advent of modern engineering and materials science, manufacturers are now able to produce bucket teeth specifically designed for optimal performance and longevity. Advanced alloy, heat treatment and investment casting technologies allow the teeth to withstand the harshest working conditions and provide superior digging power . Advanced manufacturing techniques such as computer-aided design and 3D modeling can create highly specialized bucket teeth to meet the specific needs of different industries .

The development of bucket teeth not only improves the performance of heavy machinery, but also has a positive impact on safety and environmental sustainability. By increasing digging efficiency and reducing the need for frequent replacements, modern bucket teeth help provide a more sustainable and cost-effective approach to construction and mining operations. Additionally, the durability of advanced bucket teeth ensures a safer working environment, minimizing the risk of equipment failure and potential accidents on the working site .

According to the constantly updated market demand,we continuously develop new products as per OEM samples to meet customers’ needs .If there are special appearance or material requirements, we can customize as per customers’ drawings or samples .

Our technical team ever worked for NINGBO TONGDA CASTING, who have first-class technical ability . Among them, the technical supervisor has more than 20 years of experience in the development and production of teeth and structure parts ,ever served many leading companies as BYG,PENGO,JCB,FEURST,JOC ....

.png)

.png)