Caterpillar J series bucket teeth establish a global standard. Their superior design and robust construction provide excellent performance. They work exceptionally well across many diverse applications. The CAT J SERIES is a top choice for demanding earthmoving tasks. This widespread use highlights their reliability and efficiency in various industries.

Key Takeaways

- Caterpillar J Series bucket teeth last a long time. They use strong steel and a tough design. This means less time fixing machines and lower costs.

- These teeth dig very well. They cut through hard dirt easily. This helps workers finish jobs faster and move more material.

- Caterpillar J Series teeth have smart features. They change quickly and sharpen themselves. This makes them easy to use and keeps them working great.

Unmatched Durability and Longevity of Caterpillar J Series Bucket Teeth

High-Quality Material Composition

Caterpillar J series bucket teeth achieve exceptional durability through their superior material composition. Manufacturers use high-quality alloy steel for these teeth. For example, the Caterpillar J700 HD Penetration Tooth features alloy steel, known as a high wear-resistant material. Similarly, Caterpillar Style J250 Replacement Bucket Teeth are also made from high-specification alloy steel. This specialized alloy steel contains precise amounts of elements like carbon, manganese, silicon, and chromium. These carefully selected components ensure the teeth withstand harsh digging conditions and resist wear effectively.

Robust Design for Impact and Abrasion

The robust design of these bucket teeth further enhances their longevity. Caterpillar J-Series bucket teeth are manufactured from alloy steel and undergo advanced heat treatment. This process significantly improves their durability and impact resistance. The high-specification alloy steel used in J Series bucket teeth has a hardness range of HRC46-52. It also boasts an impact resistance of ≥20J. Engineers specifically design these teeth to maximize resistance against impact, penetration, and abrasion. This ensures they perform reliably in demanding environments.

Reduced Downtime and Maintenance Costs

This combination of high-quality materials and robust design directly translates into reduced downtime and lower maintenance costs for operators. Durable Caterpillar J series bucket teeth last longer on equipment. This means machines spend more time working and less time in the repair shop. Operators replace teeth less often. Fewer replacements reduce the need for spare parts and labor. Ultimately, this saves money and increases operational efficiency for businesses.

Optimized Performance and Productivity with Caterpillar J Series Bucket Teeth

Superior Penetration and Digging Efficiency

Caterpillar J series bucket teeth significantly improve digging efficiency. Their sharp, optimized profiles allow excavators to cut through tough materials with less effort. This design reduces the force needed to penetrate the ground. Operators experience faster cycle times. The teeth also minimize wear on the machine itself. This superior penetration means equipment moves more material in less time. It directly boosts overall productivity on job sites.

Versatility Across Applications

The versatility of Caterpillar J series bucket teeth makes them suitable for many different jobs. They perform well in mining operations and rock excavations. They are also effective in quarrying and breaking through hard, rocky soil. For example, Single Tiger Teeth excel at breaking through compact materials, penetrating compact soil and clay, and digging in hard, compacted materials. Twin Tiger Teeth are ideal for digging ditches and narrow trenches. Heavy-Duty Teeth handle rock excavation, mining, and extremely abrasive soil conditions. This wide range of applications ensures operators find the right tooth for any task.

Enhanced Load Retention

Caterpillar J series bucket teeth also offer enhanced load retention. Their design helps the bucket hold material securely. This means less spillage during transport. The teeth’s shape and fit prevent material from falling out of the bucket. Operators can move more material with each pass. This efficiency reduces the number of trips needed. It saves time and fuel, making operations more cost-effective.

Innovative Design and Global Support for Caterpillar J Series Bucket Teeth

Hammerless Retention System

Caterpillar J series bucket teeth feature an innovative hammerless retention system. This design allows for quick and safe tooth changes. Operators can replace worn teeth without using hammers. This reduces the risk of injury on the job site. It also speeds up maintenance tasks. The system ensures a secure fit, keeping teeth firmly in place during operation.

Self-Sharpening Profile

The self-sharpening profile of these bucket teeth maintains optimal digging performance over time. Penetration Plus tips have a low-profile shape. This shape ensures optimal sharpness and digging ability throughout their lifespan. These genuine Cat tips resist blunting. They also self-sharpen during wear. This design leads to less downtime and reduced operating costs. It also increases productivity. These tips possess 30% more wear material than general purpose tips. They offer 10-15% more usable life. They also have 25% less cross-sectional area. The Extra profile also features a self-sharpening mechanism. This enhances penetration and abrasion resistance. The teeth are cast from premium high-strength steel. They also feature a reinforced box end for superior durability.

Broad Range of Tooth Styles and Sizes

Caterpillar offers a broad range of tooth styles and sizes for the J Series. This ensures a perfect match for any application. Available styles include:

- ABRASION TOOTH

- HD PENETRATOR TOOTH

- ROCK PENETRATOR TOOTH

- DIRT TOOTH

- HD TOOTH

- ROCK CHISEL TOOTH

- TWIN TIGER TOOTH

- Standard Tooth

- FLARE TOOTH

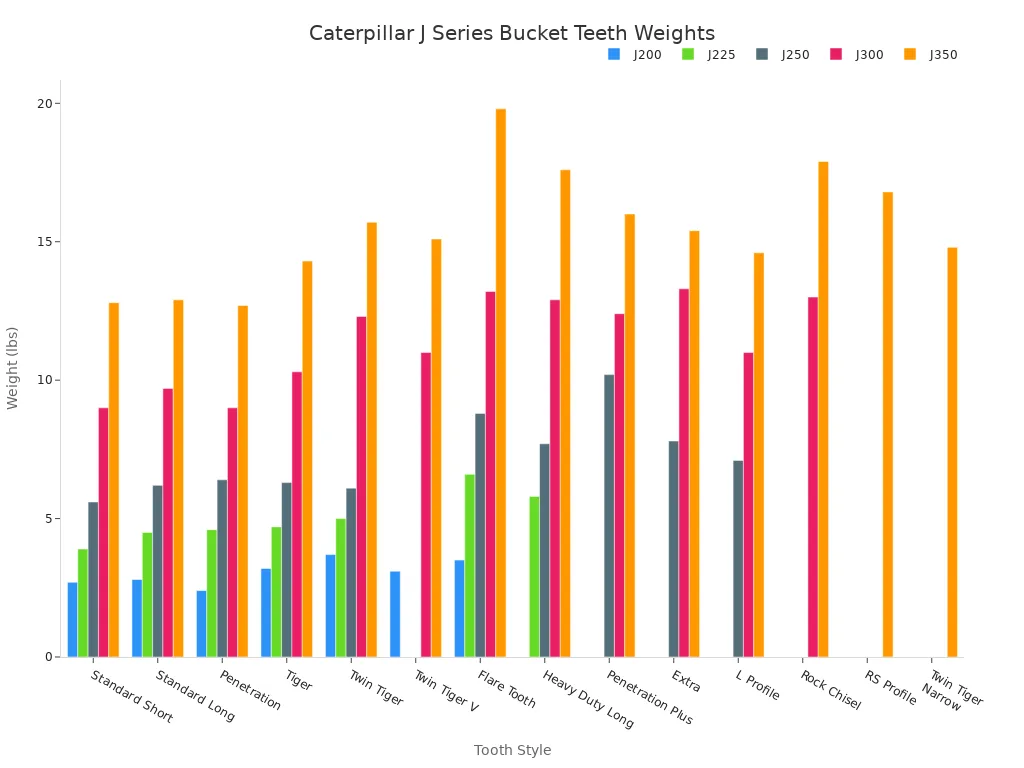

These teeth come in various sizes to fit different machine classes. For example, J200 teeth fit 0-7 ton equipment. J250 teeth are for 6-15 ton mini excavators. J300 teeth suit 15-20 ton excavators. J350 teeth work with 20-25 ton equipment. Larger sizes like J550 to J800 fit 40-120 ton equipment. The table below shows some common tooth styles and their weights across different J-Series sizes.

| Tooth Style | J200 (Weight) | J225 (Weight) | J250 (Weight) | J300 (Weight) | J350 (Weight) |

|---|---|---|---|---|---|

| Standard Short | 2.7 lbs | 3.9 lbs | 5.6 lbs | 9.0 lbs | 12.8 lbs |

| Standard Long | 2.8 lbs | 4.5 lbs | 6.2 lbs | 9.7 lbs | 12.9 lbs |

| Heavy Duty Long | N/A | 5.8 lbs | 7.7 lbs | 12.9 lbs | 17.6 lbs |

| Penetration Plus | N/A | N/A | 10.2 lbs | 12.4 lbs | 16.0 lbs |

| Extra | N/A | N/A | 7.8 lbs | 13.3 lbs | 15.4 lbs |

| RS Profile | N/A | N/A | N/A | N/A | 16.8 lbs |

| Rock Chisel | N/A | N/A | N/A | 13.0 lbs | 17.9 lbs |

| Penetration | 2.4 lbs | 4.6 lbs | 6.4 lbs | 9.0 lbs | 12.7 lbs |

| Tiger | 3.2 lbs | 4.7 lbs | 6.3 lbs | 10.3 lbs | 14.3 lbs |

| Twin Tiger | 3.7 lbs | 5.0 lbs | 6.1 lbs | 12.3 lbs | 15.7 lbs |

| Twin Tiger V | 3.1 lbs | N/A | N/A | 11.0 lbs | 15.1 lbs |

| Twin Tiger Narrow | N/A | N/A | N/A | N/A | 14.8 lbs |

| Flare Tooth | 3.5 lbs | 6.6 lbs | 8.8 lbs | 13.2 lbs | 19.8 lbs |

| L Profile | N/A | N/A | 7.1 lbs | 11.0 lbs | 14.6 lbs |

Extensive Global Availability and Support

Caterpillar maintains an extensive global network. This network provides widespread availability and support for J Series bucket teeth. Customers can easily find genuine parts and expert service worldwide. This global presence ensures that operators receive timely assistance. It also guarantees access to the right teeth for their equipment. This strong support system minimizes downtime and keeps operations running smoothly.

Caterpillar J series bucket teeth are widely used globally. Their superior durability, optimized performance, and innovative design contribute to this. Extensive global support also plays a key role. These factors make them the preferred choice for demanding earthmoving operations worldwide.

FAQ

What makes Caterpillar J Series bucket teeth so durable?

Caterpillar J Series bucket teeth use high-quality alloy steel. Manufacturers also apply advanced heat treatments. This combination provides superior resistance to impact and abrasion. This ensures long-lasting performance.

Can operators use J Series teeth on any excavator?

J Series teeth are designed for Caterpillar machines. However, adapters allow their use on other brands. This provides versatility for many different types of equipment.

How does the hammerless retention system help operators?

The hammerless system allows quick and safe tooth changes. Operators replace worn teeth without hammers. This reduces injury risk and speeds up maintenance tasks on the job site.

Post time: Jan-26-2026