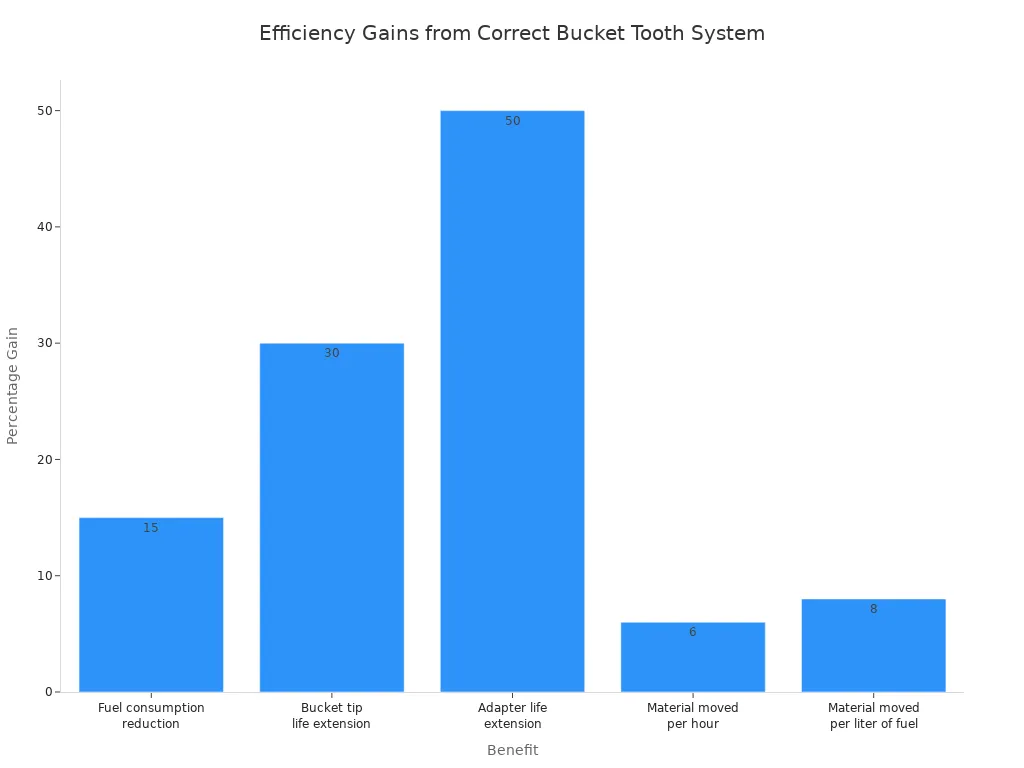

Choosing the correct CAT bucket tooth is crucial for your Caterpillar excavator. The ideal choice hinges on your specific model and its intended use. Opting for the right CAT bucket tooth system guarantees peak performance and extended durability. Understanding your machinery and its tasks will guide this selection, answering questions like Which tooth fits CAT 320/330? Ensuring proper CAT bucket tooth compatibility dramatically boosts operational efficiency, as illustrated below:

Key Takeaways

- Choose the right CAT bucket tooth for your excavator model and job. This helps your machine work better and last longer.

- Find your excavator’s serial number or check the operator’s manual. This helps you pick the correct bucket tooth system.

- Install and maintain bucket teeth correctly. This makes them last longer and keeps your work safe.

Identify Your Caterpillar Excavator Model

Accurately identifying a Caterpillar excavator model is the first step in selecting the correct bucket tooth. Each machine has specific requirements. Knowing the exact model ensures compatibility and optimal performance for any CAT bucket tooth system.

Locate Your Machine’s Serial Number

The serial number, also known as the Product Identification Number (PIN), uniquely identifies each Caterpillar excavator. This number provides crucial details about the machine’s manufacturing and specifications. Operators can find the serial number in several common locations:

- On the right side exterior of the operator’s cab, positioned below the window.

- For models manufactured before 1990, a secondary VIN plate might be on the left side of the operator’s seat when opening the door.

- Another location for pre-1990 models is on the curb side inside the cab, near the operator’s right foot.

- Older 215, 225, and 235 model machines have the VIN plate attached to the curb side of the boom arm, just above the ladder.

- Other common spots include the main frame, on the right-hand side, either below the cab or near the boom base.

- A secondary plate often resides inside the cab door frame.

Understand Model Designations

Caterpillar uses specific model designations to categorize its excavators. These designations, such as “320″ or “336,” indicate the machine’s size, power, and generation. Understanding these numbers helps narrow down the appropriate CAT bucket tooth options. For example, a “D” or “E” suffix often denotes a newer series with updated features.

Consult Your Operator’s Manual

The operator’s manual is an invaluable resource for any Caterpillar excavator owner. It contains comprehensive information specific to the machine, including recommended CAT bucket tooth systems and part numbers. This manual provides precise details for maintenance and component selection, ensuring operators choose the correct parts for their equipment.

Caterpillar Bucket Tooth Systems Explained

Caterpillar offers several distinct bucket tooth systems. Each system provides specific advantages for different applications and machine types. Understanding these systems helps operators select the most effective tools for their work.

J-Series CAT Bucket Tooth System

The J-Series CAT bucket tooth system is a widely recognized Ground Engaging Tools (GET) system. It specifically serves wheel loader buckets. This system features a reliable side pin retention system. This design ensures secure tooth attachment. The J-Series is known for its outstanding retention capabilities, superior performance, and versatility. It offers enhanced digging performance and an extended lifespan due to its durable design. This system suits diverse operational needs.

K-Series CAT Bucket Tooth System

The K-Series CAT bucket tooth system represents an evolution in bucket tooth technology. It builds upon the foundation of earlier designs. This system often provides improved retention and wear characteristics. Operators find it a robust option for various digging and loading applications. It offers a balance of performance and durability for many excavator models.

Advansys CAT Bucket Tooth System

The Advansys CAT bucket tooth system offers significant advancements. It features a hammerless system with integrated retention components. This design simplifies installation and streamlines retrofitting. It provides a safer, more efficient process with less downtime. The system allows for quicker tip removal and installation. Tapered tip sides reduce drag, which leads to higher productivity. New and optimized tip shapes place wear material where it is most needed. Stronger adapter noses achieve a 50% stress reduction, extending adapter life. A retainer lock requires no special tools for the quickest hammerless tip removal and installation. This system adapts to fit any bucket in the industry due to its wide range of sizes. It also offers a longer product life, resulting in more cost-effective operation.

“The hammerless technology is a huge benefit to us. Easy – almost no downtime. One wrench, from 180 degrees pops it right off. Safety, you know, you’re not hammering. You’re not having to pry on anything. Advansys is a good fit.”

– Chad Varney, Equipment Manager, Superior Ready Mix

Matching the CAT Bucket Tooth System to Your Excavator

Selecting the correct bucket tooth system for a Caterpillar excavator requires careful consideration of the machine’s size and intended use. Different systems offer specific benefits that align with various operational demands. Matching the system properly ensures maximum efficiency and extends component life.

Compatibility by Excavator Size

Excavator size plays a crucial role in determining the appropriate bucket tooth system. Smaller excavators typically use lighter-duty systems, while larger machines require more robust solutions. For instance, smaller to medium-sized excavators often utilize compatible CAT bucket tooth series such as J250, K80, K100, K110, and K130. These series provide reliable performance for general excavation tasks. Larger Caterpillar excavators, including models like the CAT345C L, CAT385C FS, CAT385C L, CAT385B, CAT385C, and CAT390D, demand heavy-duty teeth. The 1U3302 Caterpillar Bucket Tooth, specifically designed for the J300 series, is a common choice for these larger machines, offering enhanced durability and penetration for demanding applications.

System Advantages for Different Machines

Each Caterpillar bucket tooth system offers distinct advantages tailored to specific machine types and applications. The J-Series, for example, excels in wheel loader applications, providing secure retention and strong digging performance. Its design focuses on durability and versatility for various loading tasks. The K-Series represents an advanced option, offering improved retention and wear characteristics suitable for a broad range of excavators. This system balances performance and longevity, making it a popular choice for general excavation and material handling. The Advansys system, with its hammerless design, provides significant benefits across many excavator sizes. It simplifies installation and removal, reducing downtime and enhancing safety for operators. This system’s optimized tip shapes and stronger adapter noses also contribute to higher productivity and extended component life, making it ideal for operations prioritizing efficiency and reduced maintenance.

Upgrading Older CAT Bucket Tooth Systems

Upgrading older bucket tooth systems can significantly improve an excavator’s performance, safety, and operational costs. Many older machines can retrofit with newer, more advanced systems like Advansys. This upgrade often leads to several benefits. Operators experience safer tooth changes due to hammerless technology, eliminating the need for dangerous hammering. The improved designs of newer systems also reduce drag, which increases productivity and fuel efficiency. Furthermore, advanced materials and designs extend the lifespan of the teeth and adapters, leading to fewer replacements and lower overall maintenance expenses. Upgrading older systems represents a strategic investment that enhances both the machine’s capabilities and the safety of the work environment.

Choosing the Right CAT Bucket Tooth Style for Your Application

Selecting the correct CAT bucket tooth style directly impacts an excavator’s efficiency and the quality of work. Different applications demand specific tooth designs for optimal performance and durability.

General Purpose CAT Bucket Teeth

General purpose CAT bucket teeth handle a wide range of tasks. They are suitable for various materials.

- Typical Applications:

- Digging, loading, carrying, leveling, grading, and dumping in diverse materials.

- Ideal for construction, landscaping, industrial, and more aggressive demolition tasks.

- Design Characteristics:

- Low back height profile and long floor length provide excellent visibility and superior loading/dumping.

- Formed back wrapper and optimum wrapper angle contribute to visibility and efficiency.

- Full-length skid bars enhance floor rigidity and wear resistance.

- Hardened steel base and side cutting edges provide excellent penetration, durability, and wear life.

- Available with bolt-on cutting edge, bolt-on teeth, and bolt-on tooth bar options.

Rock Penetration CAT Bucket Teeth

For breaking through hard rock, CAT bucket teeth are designed for maximum penetration. They feature a sharp spade design to effectively slice into dense material. These teeth boast approximately 120% more material in high wear areas for superior durability. They have a slimmer leading edge with 70% less cross-sectional area compared to Heavy Duty Abrasion tips, which improves penetration. They are crafted from high-strength materials like hardened steel or tungsten carbide. An aggressive leading edge design further enhances their digging ability. These teeth also offer greater nose strength and extended fatigue life, making them ideal for challenging rock excavation. For conditions involving both high impact and severe abrasion, such as quarry operations, the material composition is critical. Alloy steel is the preferred material due to its stable quality, longer wear life, and better reliability, ensuring endurance against constant pounding and scraping. High-spec alloy steel, often combined with precise heat treatment, provides both wear-resistant and impact-resistant properties, making them perfect for environments where teeth face continuous abuse. Specialized CAT bucket teeth like the CAT ADVANSYS™ SYSTEM and CAT HEAVY DUTY J TIPS are designed for maximum penetration and superior wear life in demanding quarry conditions, utilizing proprietary alloys and heat treatments for enhanced wear and impact resistance.

| Tooth Type | Penetration | Impact | Wear Life |

|---|---|---|---|

| CAT ADVANSYS™ SYSTEM | Maximum | High | Improved adapter-to-tip wear life ratio, enhanced wear life ratio |

| CAT HEAVY DUTY J TIPS | Maximum | High | Excellent (in abrasive conditions) |

Heavy Duty Abrasion CAT Bucket Teeth

Heavy Duty Abrasion teeth resist wear in highly abrasive materials. They feature extra material in critical wear areas. This design extends their lifespan when working in sand, gravel, or other abrasive soils.

Extreme Service CAT Bucket Teeth

Extreme Service teeth handle the most demanding conditions. They combine high impact resistance with superior abrasion protection. These teeth are ideal for quarry work, demolition, and other severe applications.

Specialized CAT Bucket Tooth Designs

Beyond standard types, specialized CAT bucket tooth designs exist for unique tasks. These include designs for specific material handling, trenching, or finishing work. They offer tailored solutions for particular job requirements.

Genuine Caterpillar vs. Aftermarket CAT Bucket Teeth

Choosing between genuine Caterpillar bucket teeth and aftermarket options involves evaluating several factors. Each choice presents distinct advantages and considerations for excavator owners.

Benefits of Genuine CAT Bucket Teeth

Genuine Caterpillar bucket teeth offer specific advantages in durability and performance. Their optimized design ensures maximum excavation efficiency. These teeth are crafted for an extended lifespan, which reduces maintenance costs over time. They suit various environments and workloads, providing versatile applications. A reliable retention system keeps teeth secure even in challenging conditions, improving productivity and reducing downtime. For example, the Cat J Series System provides enhanced digging performance and an extended lifespan. The Cat Advansys™ System further improves the adapter-to-tip wear life ratio, leading to fewer replacements. This system is built for increased wear life and withstands demanding, high-production conditions, effectively controlling operational costs by minimizing maintenance and increasing reliability.

Considerations for Aftermarket CAT Bucket Tooth Options

When evaluating aftermarket bucket tooth options, operators must consider several key factors. They should first evaluate the construction application and tooth design. Selecting a tooth profile appropriate for the specific task, such as a Tiger or Twin Tiger for hard ground, ensures optimal performance. Checking equipment compatibility is crucial; verify machine limits, size specifications, and overall equipment compatibility. This is especially important for smaller compact equipment. Operators should also consider wear resistance and OEM quality. They must choose teeth with a high consumption ratio and wear resistance for long-lasting performance. Seeking expert advice from OEM dealers can provide guidance on tooth selection and maintenance. Furthermore, always verify dimensions against OEM specifications for aftermarket parts to ensure proper shank fit and adapter compatibility. Be wary of vendors who cannot provide material certifications or dimensional drawings.

Quality and Performance Differences

Significant quality and performance differences exist between genuine Caterpillar and aftermarket bucket teeth. Genuine OEM teeth often include warranties and guarantee fitment, ensuring compatibility and reliability. Premium aftermarket brands can offer competitive quality, sometimes even outperforming OEM options in wear tests, often at a better value. Mid-tier forged steel teeth provide solid performance at a lower cost, typically featuring 500+ Brinell Hardness Number (BHN). However, ultra-cheap imports should be avoided unless third-party tested, as their quality can be inconsistent. The material composition of high-quality teeth, typically alloyed carbon or manganese steel heat-treated to 450–600 BHN, directly impacts their wear life and impact resistance.

| Consideration | OEM-Branded Teeth | Premium Aftermarket Brands | Mid-Tier Forged Steel Teeth |

|---|---|---|---|

| Cost | 20–40% more than aftermarket | Competitive with OEM, potentially better value | Lower cost than OEM/premium aftermarket |

| Warranty/Fitment | Often include warranties and guaranteed fitment | May offer better value, compete closely on quality | Solid performance at lower cost |

| Quality | High | High, some outperform OEM in wear tests | 500+ BHN hardness, solid performance |

| Recommendation | Guaranteed compatibility | Check user feedback and warranty | Avoid ultra-cheap imports unless third-party tested |

How to Find the Exact CAT Bucket Tooth Part Number

Finding the precise part number for a bucket tooth ensures correct fit and optimal performance. Several reliable methods exist for identifying the exact component needed for a Caterpillar excavator.

Using the Caterpillar Part Store

The Caterpillar Part Store offers a comprehensive online resource for identifying parts. Machine owners can access detailed diagrams and part numbers directly through this platform. To use the store effectively, users typically need the excavator’s serial number or model designation. Entering this information allows the system to display compatible parts, including various bucket tooth options. The Part Store provides a visual guide, helping users confirm the correct tooth style and fitment before ordering. This digital tool streamlines the identification process, making it convenient for operators and maintenance personnel.

Consulting Your Dealer for CAT Bucket Teeth

Caterpillar dealers possess extensive knowledge and resources for parts identification. They offer expert assistance in finding the correct bucket tooth part number. When contacting a dealer, providing specific details helps them quickly identify the right component. First, inspect any existing bucket teeth for part numbers. These numbers are often on the top or side. Sometimes, manufacturers place them in less worn areas like the back or internally. Next, determine the machine’s size or model. This information significantly helps narrow down the correct options. Identify the type of bucket tooth locking system. This includes whether a pin goes through the side or top of the tooth base. Take detailed measurements and photos of the tooth. Focus on the back and base, specifically the rectangular box section. Measure the width and height of the tooth. Also, measure the depth of the box section. Additionally, identify the machine’s make and model. Note if the bucket is original or a replacement from a different manufacturer. OEMs often use exclusive systems. Measure both the inside and outside dimensions of the tooth pocket. This includes left-to-right and top-to-bottom. Provide the bucket’s lip thickness. This helps determine the correct adapter size. Supply pictures of the tooth pocket, retainer hole, and the shank itself. These visuals assist expert staff in quick identification.

Cross-Referencing Existing CAT Bucket Teeth

Existing bucket teeth often carry part numbers directly on their surface. Locating these numbers provides a direct path to identifying replacements. However, wear and tear can sometimes obscure these markings. If a part number is visible, users can cross-reference it with online catalogs, dealer databases, or aftermarket suppliers. This method works well for direct replacements. If the numbers are unreadable, comparing the physical characteristics of the worn tooth to new ones in catalogs can help. This involves matching the tooth’s shape, size, and attachment mechanism. This approach requires careful observation and comparison to ensure accuracy.

Proper Installation and Maintenance of CAT Bucket Teeth

Proper installation and consistent maintenance are essential for maximizing the performance and lifespan of excavator bucket teeth. Adhering to correct procedures ensures safety and operational efficiency.

Safety Precautions for CAT Bucket Tooth Replacement

Safety is paramount during bucket tooth replacement. Operators must turn off the power and engine before starting work. This prevents accidental movement of the bucket arm. Avoid having multiple people work on the same side of the bucket simultaneously to prevent injuries. When using a sledgehammer, maintain a firm stance to avoid losing balance from recoil. Choose a dry and flat work area to prevent tools from slipping. Secure the excavator in neutral and engage the handbrake. If necessary, place triangular wooden blocks under the tires or tracks for added stability.

Correct Pin and Retainer Installation

Correctly installing pins and retainers secures the bucket teeth. First, inspect the adapter for damage like rust or nicks; repair or replace it if necessary. Clean the tooth and adapter, ensuring they are free from dirt. Position the bucket with teeth parallel to the ground, using supports like wooden blocking. Obtain a new pin and retainer. Place the retainer into the adapter’s recess. Align the new tooth onto the adapter, ensuring the retainer stays in place. Insert the pin through the tooth and adapter from the side opposite the retainer, with the recessed end going in first. Hammer the pin until it is fully seated and flush with the end of the tooth. The recess in the pin will then securely lock into the retainer.

Regular Inspection for Wear on CAT Bucket Teeth

Regular inspections identify wear and prevent further damage. Look for excessive wear, such as tips worn through on the bottom or cracked in the pocket area. Observe uneven wear, like scalloping between teeth. Check for cracks on base edges, around adapters, on corner welds, or on sidewalls. Significant wear into adapters also indicates a problem. Loose or missing pins, or pins that move easily, require immediate attention. Dull, chipped, or cracked teeth reduce penetration and scooping effectiveness. Reduced length impacts digging efficiency and increases strain on the hydraulic system.

Maximizing CAT Bucket Tooth Lifespan

Maximizing tooth lifespan involves proactive maintenance. Conduct regular inspections every 50-100 operating hours, especially after working in abrasive environments. Promptly replace worn components to prevent further damage. Lubricate pins and bushings to prevent excessive wear. Apply anti-corrosion spray, clean adapters regularly, and store equipment in a dry, covered area. Use only compatible bolts and adapters designed for the machine. Implement proactive maintenance and replacement strategies. Skilled operators extend lifespan through proper technique; improper methods shorten it. Clean teeth after each use and periodically measure tooth dimensions to predict replacement needs.

Selecting the correct CAT bucket tooth is vital for excavator efficiency and safety. Operators must always verify their excavator model and application needs for the right CAT bucket tooth. Utilize available resources to find the precise part number. This ensures optimal performance and longevity for the equipment.

FAQ

How does one identify a Caterpillar excavator model?

Operators locate the machine’s serial number on the cab or frame. They also consult the operator’s manual for specific model designations and details.

What is the primary advantage of the Advansys CAT bucket tooth system?

The Advansys system offers hammerless installation and removal. This design improves safety and reduces downtime. It also features optimized tip shapes for higher productivity.

Why is proper installation of CAT bucket teeth crucial?

Correct installation ensures maximum performance and extends the lifespan of the teeth. It also prevents premature wear and reduces operational costs.

Post time: Dec-29-2025