Caterpillar bucket teeth enhance heavy excavation equipment’s digging, prying, and loading capabilities. They provide durable, sharp points that penetrate tough materials. Genuine Caterpillar heavy duty bucket teeth utilize premium-grade alloy steel, enriched with elements like chromium and molybdenum. Advanced heat treatment ensures their superior strength and wear resistance, optimizing material handling and protecting the bucket lip.

Key Takeaways

- Caterpillar bucket teeth help excavators dig, pry, and load materials better. They are strong and sharp, so they can get through tough ground.

- These teeth protect the main bucket from damage. They take the wear and tear, which saves money on repairs and makes the bucket last longer.

- Using the right bucket teeth makes digging faster and more efficient. This means the machine uses less fuel and gets more work done.

Core Functions of Caterpillar Heavy Duty Bucket Teeth in Excavation

Enhancing Material Penetration and Breakout Force

Caterpillar heavy duty bucket teeth significantly improve an excavator’s ability to penetrate tough materials. Their design focuses on maximizing the initial point of contact. Pointed teeth are ideal for fast soil penetration. This design makes them highly effective for operations needing excellent penetration in soft soil and general rock conditions. For example, the Caterpillar J200 Series 9W-8209 bucket tips are specifically designed for enhanced material penetration. These tips feature a leading edge with 60% less cross-sectional area. This allows for maximum penetration into densely compacted materials. A single center rib is also part of their design. This rib self-sharpens as it wears, extending service life and reducing downtime. This superior penetration translates directly into greater breakout force, allowing the machine to dislodge and move more material with each cycle.

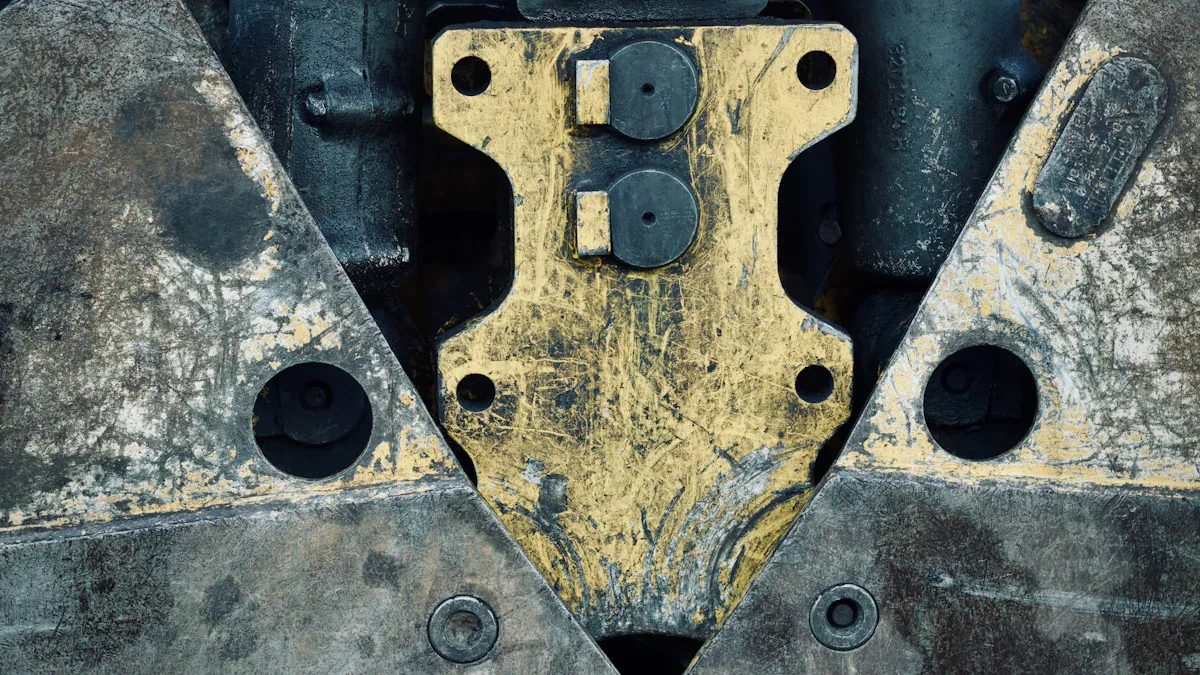

Protecting the Bucket Lip and Structure

Bucket teeth serve as a crucial protective barrier for the excavator’s main bucket structure. They are the first point of contact with abrasive materials, absorbing the brunt of wear and impact. Without adequate tooth protection, the bucket lip and adapter shanks face direct exposure to damage. Missing or severely worn teeth expose the adapter shank or lip plate. This leads to rapid damage to welds or housing. A missing tooth exposes the bucket adapter and can cause rapid damage. Dull, cracked, or missing teeth reduce digging power and increase fuel consumption. Loose or broken teeth, if not replaced, can damage the adapter pocket and lip. Ignoring small cracks in teeth can lead to crack propagation. This causes tooth breakage during digging and additional damage to the adapter or bucket lip. By sacrificing themselves, these Caterpillar heavy duty bucket teeth prevent costly repairs and extend the overall lifespan of the bucket.

Optimizing Loading and Digging Efficiency

Properly designed and maintained bucket teeth are essential for maximizing an excavator’s operational efficiency. Most of the energy consumed during hydraulic excavator operations goes into overcoming digging resistance. Therefore, reducing digging resistance is essential to improving the excavator’s efficiency and fuel consumption. The bucket teeth, at the tip of the bucket, directly contact the material. Their cutting force directly affects the overall digging resistance. Optimized bucket teeth achieved a 3.3% increase in bucket-filling ratio. There was also a 2.45% improvement in specific energy consumption. This means the machine uses less energy to move a given amount of material. Controlled production studies showed that simply changing the profile of bucket tips on a Cat 980 wheeled loader led to a 6% increase in material moved per hour. This demonstrates how the right teeth significantly boost productivity and lead to faster cycle times.

Types of Caterpillar Bucket Teeth and Their Specialized Applications

Choosing the correct bucket teeth significantly impacts an excavation project’s success. Different tooth designs cater to specific ground conditions and material types. Understanding these specialized applications helps operators maximize efficiency and extend equipment life.

Chisel Teeth for General Purpose Digging

Chisel teeth are a versatile option for everyday excavation tasks. They feature a broad design that narrows into a flat chisel shape at the working edge. This wide profile creates a large surface area. It resists abrasive terrain and wears down more slowly than pointed designs. Chisel teeth are ideal for general hauling and material loading. They perform well when leveling and trenching in loose soil. Operators also use them for excavating sand, gravel, and topsoil. Projects requiring flat-bottom trenches particularly benefit from their design. Their edges remain relatively sharp through use, maintaining performance as material wears away. However, they offer less aggressive penetration compared to more pointed designs.

Rock Chisel Teeth for Abrasive and Hard Materials

Rock chisel teeth are engineered for extreme durability in rocky and abrasive environments. They are an enhanced version of chisel teeth, featuring extra material thickness for heavy impact in hard rock. This design provides more weight and steel for a longer service life. These teeth are built from reinforced alloys for extreme impact resistance. They often incorporate hard materials like tungsten carbide to withstand wear and minimize deterioration. High-grade alloy steel or carbide ensures maximum durability. It provides the highest level of wear resistance and retains sharpness even under extreme pressure. Heavy-duty Rock Chisel Teeth utilize advanced alloy steels such as Hardox 400 or AR500. These materials offer a Brinell hardness of 400-500 and are typically 15-20mm thick. This makes them ideal for high impact and severe abrasion in rocky mining or demolition environments. These teeth require a balance of toughness and hardness. Manufacturers typically make them from sophisticated chrome-moly alloys with higher levels of molybdenum and nickel. They heat-treat these alloys to a moderate hardness (e.g., 450-480 HB). This ensures high impact strength and resists fracture, while still providing reasonable wear life. Using a tooth that is too hard would lead to brittleness and catastrophic failure.

Tiger Teeth for Maximum Penetration in Tough Ground

Tiger teeth are specifically designed for maximum penetration in the most challenging ground conditions. Their sharp, pointed design allows them to slice through materials that other teeth struggle with. Operators choose tiger teeth for tightly compacted terrain and rocky terrains. They excel in hard terrains and challenging surfaces like rock or frost. These teeth are highly effective in tough surfaces and when encountering large rocks. They also perform exceptionally well in compact materials, hard soil, and frozen ground. Tiger teeth are the preferred choice for breaking through shale and frost-hardened ground. They effectively penetrate compacted soil and work well between rocks. Their aggressive design ensures efficient digging in these difficult environments.

Abrasion Teeth for High Wear Environments

Abrasion teeth are built to withstand environments that cause rapid wear. Their design focuses on material composition and structural integrity to resist abrasive forces. The wear resistance of these teeth depends on fundamental properties. These include hardness (H), elastic modulus (E), and fracture toughness (K_Ic). The type of wear mechanisms also influences wear damage. The wear response is strongly system-dependent. Mechanical solicitation, the wear environment, and the presence of a third body all affect it. Highly mineralized materials, characterized by high modulus and hardness, exhibit greater resistance against blunt contact. For example, ceramic materials show superior wear resistance with the lowest mean wear depth. Composite resin offers intermediate wear resistance, while acrylic resin shows the lowest. These Caterpillar heavy duty bucket teeth are crucial for operations where material friction is a constant challenge.

Penetration Plus Teeth for Challenging Ground Conditions

Penetration Plus teeth offer an optimized design for challenging ground conditions that demand both penetration and durability. These teeth combine features from other specialized types to provide a balanced performance. They are ideal for applications where operators encounter a mix of hard-packed soil, some rock, and abrasive materials. Their design ensures effective material penetration while maintaining good wear life. This makes them a versatile choice for sites with varied ground compositions. They help maintain consistent digging performance and reduce the need for frequent tooth changes.

Benefits of Selecting the Right Caterpillar Heavy Duty Bucket Teeth

Choosing the correct bucket teeth significantly impacts excavation project success. Operators gain numerous advantages by matching teeth to specific job requirements. This strategic selection leads to more efficient, cost-effective, and safer operations.

Increased Productivity and Faster Cycle Times

Selecting the appropriate bucket teeth directly boosts productivity. Using the correct edge or teeth is essential for effective job performance. High-quality teeth, like premium systems, enhance productivity and fuel efficiency. They also offer greater wear resistance. For instance, pick-point teeth are necessary for working with extremely compact materials. A short tip radius on teeth increases breakout force. This can reduce wear on the bucket. The absence of appropriate teeth leads to reduced productivity and lower fuel efficiency. It also causes premature wear and tear.

Reduced Equipment Wear and Maintenance Costs

The right bucket teeth protect your investment. Using the wrong tooth type for the application, such as general-purpose teeth in a rock quarry, leads to rapid wear. This causes increased fuel consumption, potentially 20-30% higher. It also reduces productivity and slows cycle times. Incorrect teeth accelerate wear on other bucket components. They can even damage the bucket, arm, and undercarriage due to transmitted shock loads. Ignoring adapter wear results in loose tooth fits and rocking during operation. This dramatically accelerates wear and causes machine downtime. Proper tooth selection prevents these costly issues.

Improved Operational Safety and Reliability

Optimal tooth selection enhances operational safety and reliability. High-strength, wear-resistant alloy steel is essential for bucket tooth pins. Precision manufacturing ensures dimensional accuracy and surface quality. This reduces friction and wear. Matching accuracy between the pin, seat, and tip is crucial for stability and service life. Regular inspection of pin wear and prompt replacement of worn pins are vital. Operators must maintain perpendicularity to the working surface during digging. This avoids excessive force and damage. Choosing the appropriate bucket tooth model for the working environment reduces wear and damage. This ensures consistent performance and a safer worksite.

Caterpillar bucket teeth are indispensable for effective and efficient heavy excavation. Proper selection of the correct tooth type is critical. It maximizes performance and extends equipment longevity. These Caterpillar heavy duty bucket teeth significantly contribute to overall operational efficiency and cost-effectiveness. Strategic tooth choice and maintenance are key to successful excavation projects.

FAQ

Why does selecting the correct bucket teeth matter?

Choosing the right teeth boosts productivity and saves money. It ensures efficient digging and protects the bucket from damage. This choice directly impacts project success.

How often should operators check bucket teeth?

Operators should inspect teeth daily before work. Regular checks prevent unexpected failures and ensure safety. Timely replacement of worn teeth maintains peak performance.

What happens if operators use worn-out bucket teeth?

Worn teeth reduce digging power and increase fuel use. They also damage the bucket and other equipment parts. This leads to costly repairs and downtime.

Post time: Jan-26-2026