Achieve significant savings on your Caterpillar bucket teeth bulk order. A strategic approach to procurement ensures optimal value. Navigate market complexities to secure the best deals. Find an xcavator teeth bulk supplier offering CAT teeth factory price. An Excavator teeth bulk supplier provides reliable options.

Key Takeaways

- Buy Caterpillar bucket teeth in bulk from trusted sources. This includes the maker or approved sellers. This ensures good quality and avoids problems.

- Negotiate prices for large orders. Ask for discounts based on how much you buy. This helps you save money.

- Check the quality of the bucket teeth before you buy. Look for certifications and do quality checks. This makes sure the parts work well and last long.

Strategic Sourcing Channels for Cost-Effective Bulk Purchases

Businesses seeking to acquire Caterpillar bucket teeth in bulk at reduced costs must explore various strategic sourcing channels. Each channel presents unique advantages and considerations for procurement. Understanding these options allows for informed decisions that balance cost, quality, and supply reliability.

Direct Manufacturer and Authorized Dealers

Purchasing Caterpillar bucket teeth directly from the manufacturer or through authorized dealers offers significant benefits. This approach ensures confidence in the quality of the purchase. Caterpillar invests heavily in metallurgical research, developing stronger and more wear-resistant materials. Their proprietary designs include self-sharpening edges, variable geometry tips, and mechanically attached wear plates. These features extend the life of ground engaging tools (GET) and enhance performance.

Tip: Direct sourcing provides global Cat dealer support, comprehensive services, and robust warranties. Customers can also order online at any time, benefiting from a one-stop shop for cutting-edge solutions.

However, sourcing from unauthorized channels carries substantial risks. Mismatched pin sizes, unverified penetration ratings, and dimensional inaccuracies can lead to serious operational issues. Aftermarket teeth often struggle to balance hardness and toughness. This can result in brittleness and shattering under impact, or being too soft and deforming. Both scenarios cause premature failure, costly interruptions, and safety hazards. Fitment challenges due to slightly different dimensions can also result in a loose fit, causing excessive wear on the tooth and adapter. This increases the risk of detachment, potentially damaging the bucket or creating a job site safety risk. Less refined designs in aftermarket teeth can lead to less effective cutting profiles, requiring more machine power, increased fuel usage, and reduced overall productivity. Furthermore, significant variability exists in aftermarket teeth, with some using lower-grade materials that wear down quickly in abrasive conditions. This leads to more frequent changes, increased operational costs, and downtime. Brittle fracture under shock load and voided machine warranties also pose concerns if non-approved parts are installed. Potential non-compliance with national safety standards in some jurisdictions also exists. Consultation with the dealer is always advised before installing non-OEM parts to understand the impact on equipment warranty.

Reputable Aftermarket Suppliers

Reputable aftermarket suppliers present a viable alternative for cost-effective bulk purchases. These suppliers offer high-performance and long-term use products. They ensure OEM compatibility and reliability, often demonstrating innovation with advanced materials. A reputable excavator teeth bulk supplier provides clear material specifications, such as hardness ratings (HRC or HBW), with specific ranges for different applications. For example, general excavation teeth typically have 35-45 HRC, while heavy-duty or rock work requires 45-55 HRC. Extreme abrasion applications often use 55-63 HRC, sometimes with carbide overlays. They also provide quality certifications and verifiable manufacturing processes, such as forged versus cast.

Note: A reputable aftermarket supplier meets product quantity and delivery times. They maintain a reputation for quality products and professional skills, offering high quality at a good price. Enthusiastic and good customer service, fast delivery, and complete certifications also characterize these suppliers.

Aftermarket bucket teeth typically have a lower initial purchase price compared to genuine Caterpillar bucket teeth. However, this initial saving can be misleading. Genuine parts, while costing more upfront, offer superior durability and performance, leading to longer lifespan and fewer replacements over time. The long-term value of genuine parts often outweighs the immediate savings from cheaper alternatives. Genuine Caterpillar Bucket Teeth often prove more cost-effective and productive long-term, typically lasting 20–40% longer than aftermarket alternatives. This extended lifespan reduces downtime and replacement costs, highlighting their superior long-term value when evaluating the ‘cost per hour of operation’.

International Sourcing Opportunities

Exploring international sourcing opportunities can unlock significant cost savings for bulk purchases of Caterpillar bucket teeth. Manufacturers in certain regions offer competitive pricing due to lower production costs or favorable exchange rates. Businesses must conduct thorough due diligence when considering international suppliers. This includes verifying their manufacturing capabilities, quality control processes, and adherence to international standards. Understanding import duties, taxes, and shipping logistics becomes crucial for accurate cost assessment. Establishing clear communication channels and robust contractual agreements mitigates potential risks associated with cross-border transactions.

Online B2B Marketplaces and Platforms

Online B2B marketplaces and platforms provide convenient avenues for sourcing Caterpillar bucket teeth in bulk. These platforms connect buyers directly with numerous suppliers, fostering competitive pricing. They offer a wide selection of products, often including various types of ground engaging tools (GET). For example, myspareparts.com offers a range of GET, including bucket GET, GET adapters and components, auger components, ripper and scarifier GET, paver, compactor and demolition GET, GET wear plates and protection, GET drilling systems, GET hardware and hardware kits, and dozer GET. Utilizing these platforms allows businesses to compare prices, review supplier ratings, and streamline the procurement process. Buyers should prioritize platforms with secure payment systems and clear dispute resolution mechanisms.

Negotiation and Quality Assurance for Bulk Orders

Businesses must master negotiation and quality assurance when sourcing Caterpillar bucket teeth in bulk. These practices ensure cost savings and product reliability. A strategic approach to these areas protects investments and maintains operational efficiency.

Leveraging Volume for Price Reductions

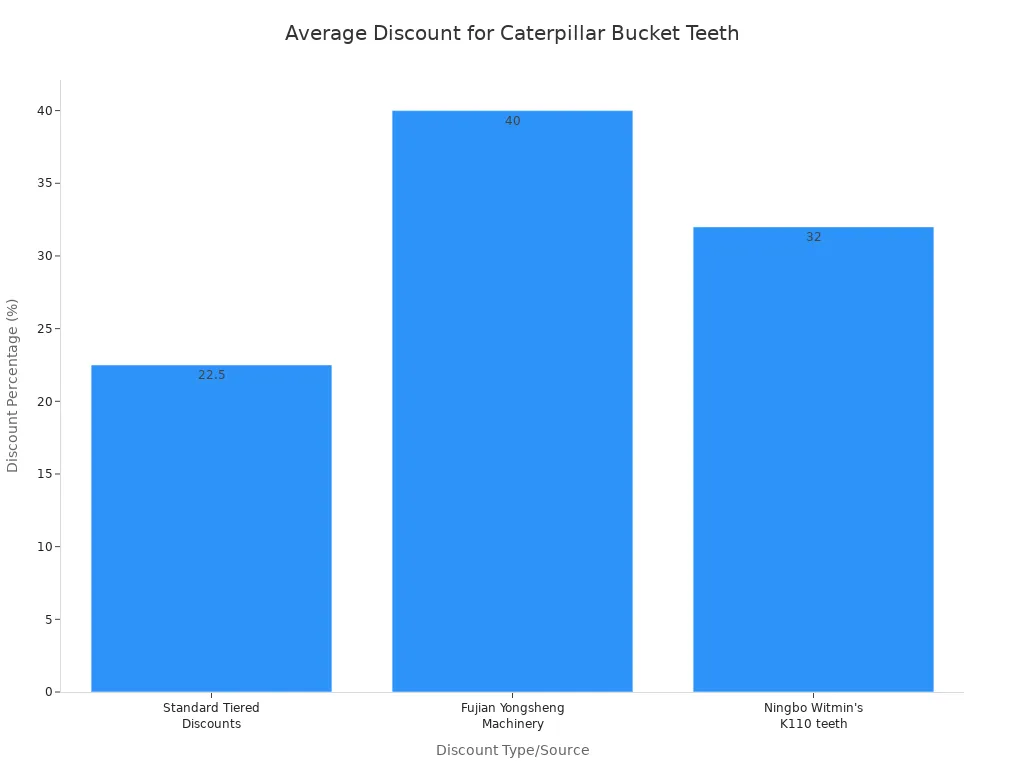

Purchasing Caterpillar bucket teeth in large quantities provides significant leverage for price negotiations. Suppliers often offer tiered discounts based on order volume. Businesses can achieve substantial savings by consolidating their needs into larger orders. For example, some suppliers offer a 40% discount for orders of 500+ units compared to 50 units. Kilogram-priced options, like Ningbo Witmin’s K110 teeth, can yield up to 32% savings for high-volume operators meeting minimum order quantities of 800kg.

| Discount Type | Discount Percentage | Conditions/Thresholds |

|---|---|---|

| Standard Tiered Discounts | 15-30% | Crossing quantity thresholds |

| Specific Example (Fujian Yongsheng Machinery) | 40% | Orders of 500+ units compared to 50 units |

| Kilogram-priced options (Ningbo Witmin’s K110 teeth) | Up to 32% | High-volume operators (e.g., 800kg MOQ) |

Effective negotiation requires thorough preparation. Businesses should conduct market analysis to understand trends and benchmark costs. They must define their value proposition, such as consistent bulk purchasing. Setting clear goals for pricing, delivery, and quality is essential. Identifying backup vendors also provides alternatives. During negotiations, building strong business relationships and using effective communication, including active listening and open-ended questions, proves beneficial. Leveraging negotiation power by highlighting order volume or market knowledge helps. Focusing on long-term collaboration fosters mutual benefits. Key areas for negotiation include pricing, payment terms, delivery schedules, and quality assurance.

Securing Favorable Payment and Supply Terms

Negotiating favorable payment and supply terms is crucial for managing cash flow and ensuring consistent product availability. Extended payment periods, milestone payments, or early payment discounts can significantly impact a buyer’s financial health. Businesses should also negotiate clear delivery schedules and lead times. This prevents operational delays. For standard bucket teeth with existing molds and stock, lead times typically range from 7-10 days for 100-500 pieces and up to 15 days for over 500 pieces. Custom castings, requiring new molds, have longer lead times, usually 30-45 days. An excavator teeth bulk supplier should clearly communicate these timelines.

| Product Type | Quantity | Standard Lead Time | Expedited Lead Time |

|---|---|---|---|

| Standard bucket teeth (existing molds/stock) | 100-500 pieces | 7-10 days | N/A |

| Standard bucket teeth (existing molds/stock) | Over 500 pieces | Up to 15 days | N/A |

| Custom castings (new molds/special processes) | Any | 30-45 days | Around 25 days (upon confirmation) |

Verifying Supplier Quality and Certifications

Verifying a supplier’s quality and certifications is paramount. This ensures the purchased bucket teeth meet required performance and safety standards. Essential industry certifications include ISO9001 and CE. These certifications indicate a commitment to quality management systems and product compliance.

| Certification |

|---|

| ISO9001 |

| Certification |

|---|

| ISO9001:2008 |

| Certification |

|---|

| CE |

| ISO9001:2008 |

Managing supplier quality is a crucial strategy for verifying manufacturing processes and quality control standards. This involves choosing the right suppliers to ensure the quality of raw materials. Raw material quality directly impacts the final product’s integrity. Implementing strict quality control measures for suppliers helps maintain consistent and high-quality standards throughout the production workflow.

Methods to verify a supplier’s manufacturing processes and quality control standards include:

- Inspection: Visually checking raw materials, in-process items, and finished products for defects or inconsistencies.

- Statistical Process Control (SPC): Using statistical tools to monitor and control processes. This identifies variations and out-of-control conditions to maintain consistent quality.

- Sampling: Selecting a random sample of products for testing. This ensures specifications are met efficiently without inspecting every item.

- Automated Testing: Employing machines to perform repetitive tests on products for parameters like strength, size, and alignment. This ensures consistency and accuracy.

- Employee Training: Ensuring workers understand quality standards and how to spot defects. They also stay updated on new quality practices.

- Root Cause Analysis: Identifying the underlying issues causing defects. This implements corrective measures and prevents recurrence.

- Preventive Maintenance: Scheduling routine checks and repairs for machines. This avoids unexpected breakdowns and ensures consistent production of high-quality products.

- Six Sigma: A data-driven method focused on reducing defects and improving processes by identifying inefficiencies and errors.

- Quality Audits: Reviewing company processes and products for compliance with quality standards. This leads to procedural improvements.

- Feedback Loops: Collecting customer feedback to identify areas for improvement. This adjusts products and processes to meet expectations.

- Taguchi Method: A statistical approach to design products and processes to be robust and less sensitive to variations. This minimizes defects.

- Benchmarking: Comparing a company’s processes or products against industry leaders or best practices. This identifies gaps and implements improvements.

- Quality Function Deployment (QFD): Translating customer needs into technical specifications. This ensures customer requirements are met in the design process.

- Poka-Yoke (Mistake Proofing): Designing processes, tools, or devices to prevent errors or make them immediately detectable.

- Andon System: A visual tool allowing employees to stop the production line if an issue is detected. This fosters ownership and responsibility for quality.

- Total Productive Maintenance (TPM): Maximizing equipment efficiency and reliability by involving all employees in maintenance tasks. This prevents breakdowns and ensures consistent product quality.

Other verification methods include conducting reference checks with a supplier’s previous clients. Placing trial orders also tests a supplier’s capabilities before committing to a long-term partnership. Performing on-site audits allows direct evaluation of production processes and adherence to standards.

Implementing Pre-Purchase Quality Checks

Implementing rigorous pre-purchase quality checks helps identify potential issues before a bulk order is finalized. A price significantly lower than the market average for Caterpillar bucket teeth often indicates underlying quality issues. Businesses should investigate these further.

Common failure modes of low-quality Caterpillar bucket teeth that pre-purchase checks can identify include:

- Lack of clear material specifications, beyond generic terms like “high-strength steel.”

- Absence of hardness ratings (HRC or HBW).

- Missing quality certifications.

- Undisclosed or unverifiable manufacturing processes, such as not specifying if forged versus cast.

These checks ensure the product meets performance expectations and avoids costly replacements or operational downtime.

Optimizing Logistics with an excavator teeth bulk supplier

Efficient logistics are crucial for cost-effective bulk procurement of Caterpillar bucket teeth. Businesses must strategically manage shipping, consolidate orders, and build strong supplier relationships. These actions minimize expenses and ensure timely delivery.

Managing Shipping and Import Costs

Managing shipping and import costs effectively reduces the overall expense of bulk orders. Caterpillar’s Manufacturer’s Suggested Retail Price (MSRP) for excavator buckets does not include shipping, handling, or taxes. Dealers set actual prices. International and interstate transactions often use FOB (Free On Board) pricing structures. These define where the seller’s responsibility for shipping costs and liability ends. This transparency helps calculate the goods’ ‘landed value’. For orders over 150 lbs, flat-rate shipping options exist, such as $185 for orders up to $1000 or $500 for orders up to $5999. An excavator teeth bulk supplier should clearly outline these costs.

Consolidating Shipments for Efficiency

Consolidating shipments significantly improves efficiency and reduces costs. Consolidated Freight Shipping combines multiple smaller shipments into a single truckload. Businesses pay only for the space used, sharing the truckload cost. Partial Truckload (PTL) Shipping suits freight volumes larger than Less Than Truckload (LTL) but less than a full truckload. PTL reduces handling and sorting. Shared Truckload (STL) Shipping combines shipments from multiple shippers with similar routes. This optimizes truck capacity and reduces costs by sharing transportation expenses. A mid-sized automotive parts manufacturer saved $50,000 annually through freight consolidation. This demonstrates the potential for heavy equipment parts. An excavator teeth bulk supplier often offers these consolidation services. Transys Global Forwarding (TGF) provides cost-effective international freight forwarding for industrial goods, optimizing routes and consolidating shipments.

Establishing Long-Term Supplier Relationships

Establishing long-term relationships with an excavator teeth bulk supplier offers numerous benefits. Long-term cooperation helps businesses grow continuously. These partnerships ensure consistent product quality and reliable supply. Businesses formalize these relationships through contractual agreements. A Framework Agreement sets general terms for an ongoing relationship. Specific ‘call-off’ orders are placed as needed. This structure includes master terms covering pricing, payment, quality standards, and dispute resolution. Individual contracts then detail specific transactions like quantity and delivery schedules. This approach streamlines procurement and ensures consistent terms across multiple transactions.

Businesses implement a comprehensive strategy for cost-effective bulk sourcing. They balance cost savings with unwavering quality and reliability. This approach ensures optimal performance. Ultimately, companies achieve substantial long-term savings for their operations. This strategic procurement delivers lasting value.

FAQ

What are the main benefits of buying Caterpillar bucket teeth in bulk?

Bulk purchasing offers significant cost savings through volume discounts. It also ensures a consistent supply, reducing operational downtime and improving efficiency for businesses.

How can businesses ensure the quality of bulk-purchased bucket teeth?

Businesses verify quality through supplier certifications like ISO9001 and CE. They also conduct pre-purchase quality checks and on-site audits of manufacturing processes.

What risks are associated with sourcing from unauthorized aftermarket suppliers?

Risks include mismatched parts, premature failure, and safety hazards. These can lead to increased downtime, higher operational costs, and potential warranty voidance.

Post time: Jan-19-2026