Safely install and remove Caterpillar bucket teeth by following precise steps and using appropriate tools. Proper procedures ensure operational efficiency. They also prevent equipment damage or personal injury. Adhering to safety guidelines is paramount for all heavy machinery maintenance. Proper maintenance leads to significant cost savings and long-term operational efficiency. Knowing how to install CAT bucket teeth correctly maximizes these benefits.

Key Takeaways

- Always use the right tools and safety gear. This keeps you safe and prevents machine damage.

- Follow all steps carefully when removing and installing teeth. This makes sure the job is done right.

- Check teeth often and replace them when worn. This helps your machine work better and last longer.

Essential Tools and Safety Gear for CAT Bucket Teeth

Proper preparation is crucial before any maintenance task. This includes gathering the correct tools and wearing appropriate safety gear. Following machine safety protocols also protects workers.

Required Tools for Removal and Installation

Technicians need specific tools for removing and installing bucket teeth. A heavy-duty hammer is essential. A punch set helps drive out retaining pins. A pry bar assists in detaching stubborn teeth. Always use tools designed for the task. This prevents damage to components and ensures worker safety.

Personal Protective Equipment (PPE)

Wearing personal protective equipment is mandatory. It protects workers from potential hazards. Essential PPE items include safety gloves. These protect hands from cuts and abrasions. Workers must wear eye protection, such as safety glasses. This shields eyes from flying debris. Steel-capped boots are necessary to protect feet from falling objects. A long-sleeve shirt also provides skin protection.

Machine Safety Protocols

Strict machine safety protocols must be in place. Always secure the machine before starting work. Park it on level ground. Engage the parking brake. Turn off the engine. Implement a lockout/tagout procedure. This prevents accidental machine startup. Clear the work area of any obstructions. Ensure good lighting. These steps create a safe environment for working on CAT bucket teeth.

Preparing for Safe CAT Bucket Teeth Removal

Secure the Machine and Work Area

Before any removal process, technicians must secure the machine and its surrounding area. They park the machine on a flat, stable surface. This prevents any unexpected movement during maintenance. They engage the parking brake and turn off the engine. Implementing a lockout/tagout procedure ensures the machine remains powered down. Clearing the work area of debris and ensuring adequate lighting creates a safe and efficient environment for the task.

Position the Bucket for Access

Proper bucket positioning is crucial for safe and efficient access to the CAT bucket teeth. Operators lower the bucket to the ground. They curl it slightly forward. This provides a stable platform for technicians. It also exposes the teeth for easier removal. Ensure the bucket is stable and positioned on a level surface to prevent any movement during the replacement process. This careful positioning minimizes strain and improves visibility for the technician.

Initial Inspection of Worn CAT Bucket Teeth

An initial inspection identifies the extent of wear on the bucket teeth. Technicians perform a visual inspection. They examine the teeth for cracks, chips, or excessive wear. They look for visible cracks or worn-through metal on the heel or bottom. Dull or missing teeth indicate significant wear. Irregular or uneven tooth patterns also signal replacement needs. Shiny, thinned-out metal on wear surfaces suggests advanced deterioration. They also check for missing or excessively worn teeth, cracks, and exposed shanks. Loose bolts, corrosion, or adapter misalignment also require attention. Technicians compare the current tooth size to original specifications. Significant size reduction indicates the need for replacement.

Step-by-Step Removal of Old CAT Bucket Teeth

Locating and Accessing the Retaining Pin

Technicians begin the removal process by positioning the bucket upward. This prevents the tips from falling unexpectedly. They obtain a tooth pin remover tool, often sourced from a Cat dealer or Parts.Cat.com. The technician aligns the tooth pin remover with the right side of the tip. They then hammer the pin remover until the retaining pin releases. After the pin releases, they remove the tip and retainer. If the retainer is stuck, they tap it with a hammer to loosen it.

Driving Out the Retaining Pin

Driving out the retaining pin requires specific tools and techniques. Technicians use a suitable pin punch, typically around 5-6 inches long, to drive out the pin. For initial strikes, a 3-pound hammer provides ample force. A larger 5-pound hammer allows for controlled force, which helps avoid damaging the adapter. Some situations may require sledgehammers, ranging from 8 to 16 pounds, for greater force application. An 8-inch long tapered punch, with a 3/8-inch diameter tip made of grade 4140 steel, assists in driving retaining devices outward. Before striking, technicians often apply penetrating oil, such as PB Blaster, to the pin. They pre-soak the pin for 15-20 minutes. This loosens rust and reduces the force needed for removal. Pre-soaking for 8-12 hours is recommended for heavy corrosion. Applying controlled force is essential. Technicians strike the punch straight on, aiming towards the tooth’s side. Direct hits are crucial. Proper alignment of the tapered punch prevents glancing blows.

Detaching the Worn Tooth from the Adapter

Once the retaining pin is out, technicians carefully detach the worn tooth from the adapter. They may use a pry bar to gently separate the tooth if it remains stuck. Sometimes, a slight tap with a hammer on the side of the tooth helps loosen it from the adapter shank. Technicians ensure they maintain a firm grip on the tooth during this process. This prevents it from falling unexpectedly. They pull the tooth straight off the adapter, avoiding twisting motions that could damage the adapter.

Collecting All Components Safely

After removing the old tooth, technicians collect all components safely. This includes the worn tooth, the retaining pin, and any washers or retainers. They place these items in a designated container for proper disposal or recycling. This practice prevents trip hazards in the work area. It also ensures no small parts get lost. Proper collection contributes to a clean and organized workspace, enhancing overall safety and efficiency. This step is crucial for maintaining a safe environment and preparing for the installation of new CAT bucket teeth.

Cleaning and Inspecting the Adapter for New CAT Bucket Teeth

Proper preparation of the adapter is crucial before installing new teeth. This step ensures a secure fit and extends the lifespan of the new components.

Thorougly Clean the Adapter Shank

Technicians must thoroughly clean the adapter shank. They use a wire brush to remove all dirt, rust, and debris. A scraper helps dislodge stubborn material. Compressed air effectively clears away fine dust particles. A clean surface ensures the new tooth seats correctly. Any remaining foreign material can prevent a tight fit. This leads to premature wear or failure of the new CAT bucket teeth.

Inspect the Adapter for Wear or Damage

After cleaning, technicians carefully inspect the adapter. They look for signs of wear, such as cracks or deformation. Excessive wear on the adapter shank can compromise the fit of the new tooth. Technicians also check the pinholes for ovaling or enlargement. Ovaled pinholes indicate significant wear. Such damage prevents the retaining pin from holding the tooth securely. If the adapter shows severe wear or damage, technicians must replace it. A damaged adapter will not properly support new teeth.

Prepare New CAT Bucket Teeth for Installation

Before installation, technicians prepare the new teeth. They visually inspect each new tooth for any manufacturing defects or damage. They confirm the new teeth match the specific adapter type and machine model. Technicians gather all necessary components, including new retaining pins and retainers. Having all parts ready streamlines the installation process. This preparation minimizes downtime and ensures a smooth transition to the next step.

Installing New CAT Bucket Teeth Securely

Correctly Position the New Tooth

Technicians carefully slide the new tooth onto the adapter shank. They ensure a snug fit. The tooth’s pinholes must align perfectly with the adapter’s pinholes. This alignment is crucial for proper pin insertion. A misaligned tooth will not seat correctly. It can lead to premature wear or failure.

Inserting the Retaining Pin

Once the new tooth is in place, technicians proceed with inserting the retaining pin. They align the pinhole on the tooth with the hole on the shank. Then, they insert the retaining pin or bolt through the aligned holes. A hammer helps drive the retaining pins into place. Alternatively, they tighten the bolts securely, depending on the tooth design. Technicians check that the pins are flush and firmly seated. This step ensures the tooth remains attached during operation.

Securing the Retaining Pin

Securing the retaining pin is vital for operational safety. Technicians drive the new pin in using a hammer until it is flush. They ensure it is fully seated to prevent the tooth from falling off during operation. Caterpillar bucket teeth utilize a ‘Pin-on with retainer’ tooth fit style. This design offers ‘High precision locking’ and ‘Easy’ ease of replacement. Locking Pins are also equipped with a locking mechanism. This mechanism prevents loosening caused by vibration. It enhances operational safety. These pins are recommended for extended, continuous work cycles.

Verifying Proper Seating of the New Tooth

After installation, technicians perform several checks to confirm proper seating. They check pin seating. All retaining pins must be fully inserted and flush with the tooth surface. Pins sticking out can loosen during digging. Technicians confirm alignment. Teeth should line up evenly along the bucket edge. Misaligned teeth cause uneven wear and reduce digging efficiency. They verify the fit. Teeth must fit snugly on the shanks without wobbling. A loose fit leads to premature wear or tooth loss. Finally, they inspect for damage. They look for cracks, bends, or deformities in the teeth or pins. Such damage might have occurred during installation. These checks ensure the new CAT bucket teeth are ready for use.

Post-Installation Checks for CAT Bucket Teeth

After installing new teeth, technicians must perform crucial post-installation checks. These steps confirm proper installation and ensure safe operation. They prevent potential issues during work.

Double-Check All Retaining Pins

Technicians must double-check every retaining pin. They ensure each pin is fully seated and flush with the tooth surface. A loose pin can cause the tooth to detach during operation. This creates a safety hazard and leads to costly downtime. Technicians visually inspect each pin. They also apply slight pressure to confirm its stability.

Test Bucket Movement and Functionality

After attaching the new bucket, technicians test its functionality. They use the excavator’s controls to move the bucket through its full range of motion. They check for any issues or abnormalities during movement. This includes unusual noises or resistance. If everything appears to be in working order, they lower the boom. The machine is then ready for use. This test confirms the secure attachment of the new CAT bucket teeth.

Monitor Performance During Initial Operation

Operators should closely monitor the bucket’s performance during its initial operation. They listen for unusual sounds. They also observe for excessive vibration or unexpected tooth movement. Any signs of loosening or improper seating require immediate attention. Prompt action prevents further damage to the bucket or machine. It also ensures worker safety.

Maintenance Tips for Extending CAT Bucket Teeth Lifespan

Proper maintenance significantly extends the life of CAT bucket teeth. Implementing a consistent maintenance routine reduces operational costs and improves efficiency. Operators and technicians must follow specific guidelines to achieve maximum lifespan.

Regular Inspection Schedule

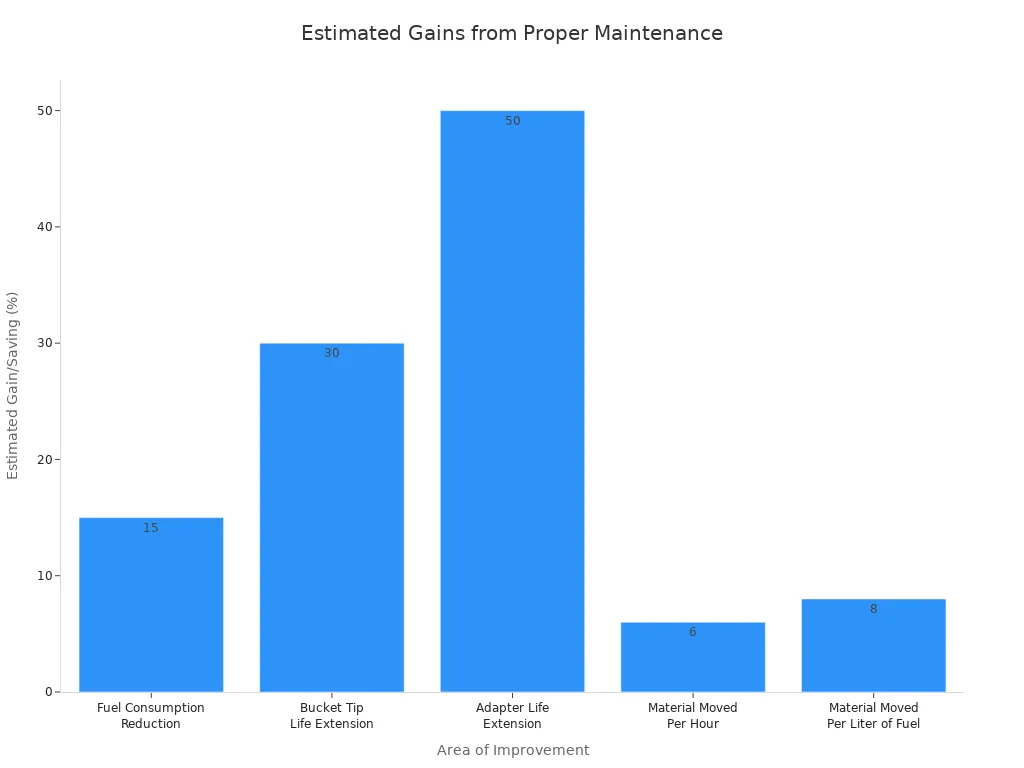

Technicians should establish a regular inspection schedule for bucket teeth. In high-intensity wear environments, such as mines and quarries, daily inspections are crucial. They conduct these inspections both before and after each operation. This helps identify signs of wear, damage, or misalignment early. Technicians clean bucket teeth after each use to remove debris. They also ensure teeth are securely fastened to prevent increased wear or loss. Replacing teeth when they are 50% worn prevents further damage to the adapter.

Optimal Operating Practices

Operator techniques directly impact tooth lifespan. Operators engage teeth at the correct angle and depth. They avoid overloading the bucket and load materials evenly. Maintaining proper operating speeds also helps. Adjusting digging angles can significantly improve durability. Operators should avoid excessive digging angles and use the appropriate digging mode for the material. They minimize unnecessary high-impact tasks. Using buckets with missing teeth is not advisable. Smooth, controlled movements are preferred over jerky actions to distribute wear evenly across the CAT bucket teeth.

Timely Replacement of Worn Teeth

Knowing when to replace worn teeth is essential. Technicians replace teeth when the tip is blunted or rounded. They also replace teeth when there is a 30-50% reduction in original length and sharpness. Immediate replacement is necessary for cracks, fractures, deformation, or broken tooth heads. Performance degradation also signals replacement. This includes a noticeable drop in excavation performance, increased fuel consumption, or longer cycle times. The type of material excavated and operating conditions also influence wear rates.

Prioritize safety and follow each step meticulously for installing and removing CAT bucket teeth. Proper maintenance significantly extends tooth life and ensures peak machine performance. Regular checks and correct procedures are key to safe and efficient operations. These practices protect equipment and personnel.

FAQ

How often should one inspect CAT bucket teeth?

Inspect CAT bucket teeth daily in high-wear environments. Check them before and after each operation. This identifies wear early.

What happens if one does not replace worn teeth promptly?

Not replacing worn teeth causes increased fuel consumption. It also reduces digging efficiency. This can damage the adapter and bucket.

Can one reuse retaining pins?

No, always use new retaining pins. Worn pins compromise security. New pins ensure a tight, safe fit for the new CAT bucket teeth.

Post time: Dec-30-2025