When comparing Caterpillar vs Komatsu bucket teeth durability, specific conditions dictate performance. Caterpillar bucket teeth often show an edge in extreme abrasive conditions. This results from proprietary alloys and heat treatment. Komatsu teeth excel in specific applications. They offer optimized designs for impact resistance. This influences the Komatsu vs CAT bucket tooth wear rate.

Key Takeaways

- Caterpillar bucket teeth often last longer in very abrasive conditions. Their special materials and heat treatments help them resist wear.

- Komatsu teeth are often better for jobs with high impact. Their design and materials help them withstand strong hits.

- Choose the right bucket teeth for your specific job. This helps them last longer and work better.

Key Factors Influencing Bucket Teeth Longevity

Material Composition and Hardness

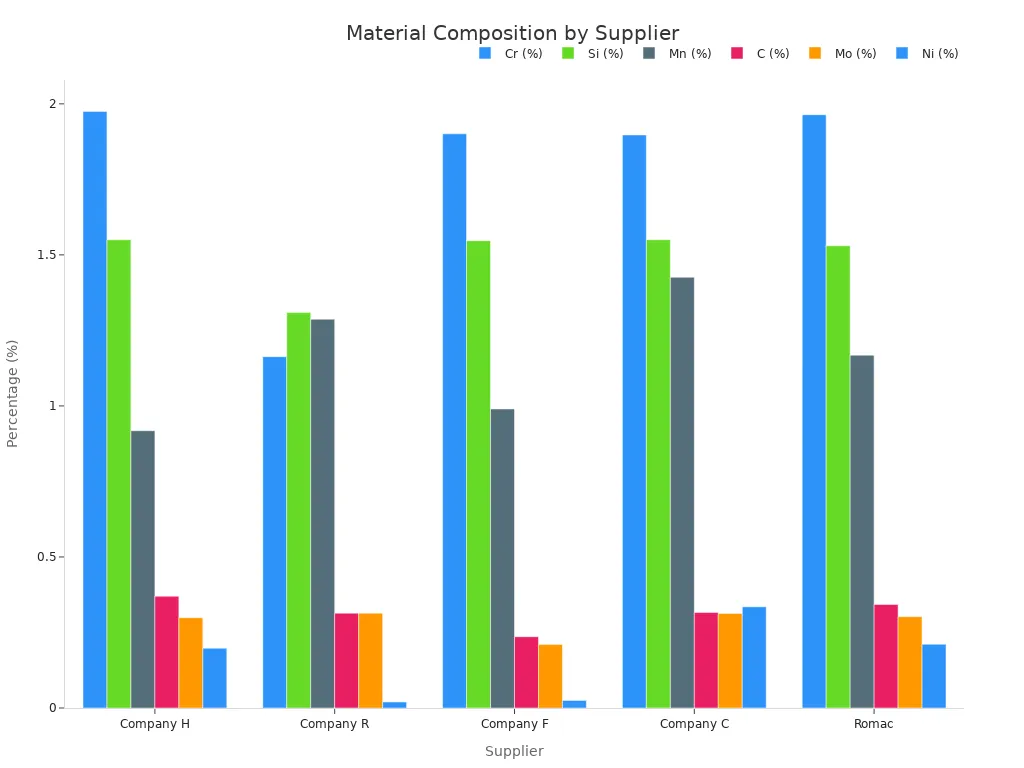

The materials used in bucket teeth significantly determine their lifespan. Manufacturers craft these teeth from alloy steel. This steel undergoes heat treatment to improve its hardness and toughness. Carbon content, typically ranging from 0.236% to 0.37%, plays a vital role in the material’s hardness and wear resistance.

Research shows a strong link between hardness and wear resistance. Higher hardness values generally mean greater resistance to wear. However, excessively hard teeth can become brittle. They might crack or fracture more easily upon impact. Manufacturers must balance hardness with impact resistance for optimal performance.

Design and Shape for Wear Resistance

The design and shape of bucket teeth also affect their durability. Specific designs minimize material loss from abrasion.

- Excavator Abrasion Teeth feature extra wear material. They handle extreme digging in abrasive materials like sand or limestone.

- Self-sharpening Bucket Teeth maintain their profile as they wear. This prevents them from becoming blunt and ensures effective penetration.

Bucket teeth engineered for high impact resistance withstand penetrating shocks. For example, Star Penetration (ST, ST9) Teeth have a star shape with a rib. This design adds strength and wear material, preventing tooth fracture in demanding conditions like rock quarries.

Application and Operating Conditions

The environment where equipment operates heavily influences bucket teeth wear. Teeth at the forefront of excavators face direct contact with materials like ores and gravel. Abrasive wear is the most common type of damage in these conditions. Non-spherical particles cause greater wear due to increased shear. Operating strategies, such as digging angles and speeds, also affect wear patterns. They can unevenly distribute stress on the teeth.

Maintenance Practices and Lifespan

Proper maintenance significantly extends the operational lifespan of bucket teeth.

- Regular inspection and cleaning minimize downtime. This includes checking for cracks, wear, and secure fasteners.

- Replacing or rotating teeth when wear appears ensures even wear. This prolongs the overall bucket lifespan.

- Monitoring wear with measurement tools helps schedule proactive maintenance. This prevents minor issues from becoming major problems.

- Timely replacement of excessively worn teeth prevents further damage to the bucket. It also maintains digging efficiency.

Caterpillar Bucket Teeth: Durability and Design Advantages

Caterpillar designs its bucket teeth for robust construction and long-lasting performance. Their manufacturing processes focus on maximizing durability, especially in challenging work environments.

Proprietary Alloys and Heat Treatment for Wear

Caterpillar uses special materials for its bucket teeth. They craft these teeth from proprietary hardened alloy steel. This steel undergoes forging and heat treatment. These processes give the teeth superior resistance to wear and impact. The specific names or exact compositions of Caterpillar’s unique alloy formulas are not publicly detailed. However, the result is a material that stands up to tough conditions. This careful material selection and treatment ensure the teeth maintain their strength and shape longer.

GET System Design for Extended Life

Caterpillar designs its Ground Engaging Tools (GET) systems for extended life. The Cat J Series, for example, aims to prolong the durability of Caterpillar bucket teeth. This reduces maintenance costs. The Cat Advansys System offers an improved adapter-to-tip wear life ratio. This means fewer replacements are necessary. It is built for increased wear life in demanding conditions. The Cat Advansys System also provides an enhanced wear life ratio for the adapter-to-tip. This leads to fewer replacements over the bucket’s lifecycle. It is built for high-production environments. The Cat CapSure System focuses on safety and efficiency during maintenance. It simplifies tip replacement. This indirectly helps component longevity. It reduces the need for forceful maintenance that might damage parts. Caterpillar bucket teeth are made using a high-quality alloy melting process. This process ensures both strength and wear resistance. Their construction uses premium-grade materials. This contributes to their extended lifespan. A heavy-duty design, including a center rib, further improves wear resistance and durability. This maintains efficiency during excavation tasks.

Performance in Abrasive Environments

Caterpillar bucket teeth excel in abrasive environments. The CAT ADVANSYS™ SYSTEM is engineered for maximum productivity. It also aims for the lowest bucket lifecycle cost in the toughest applications. CAT HEAVY DUTY J TIPS are designed for maximum penetration. They work well in heavy-to-extreme duty buckets. These tips perform powerfully in high-impact, highly abrasive conditions. They handle materials such as mixed clay, rock, shot granite, sandstone, high silica sand, caliche, ore, and slag. CAT® FLUSHMOUNT TOOTH SYSTEMS are specifically engineered to boost productivity in high-abrasion environments. They balance strength, penetration, and wear life. They effectively pierce tough materials.

Komatsu Teeth: Resilience and Innovation for Longevity

Komatsu designs its bucket teeth for resilience and long-lasting performance. The company focuses on innovative solutions. These solutions ensure durability in demanding work environments.

Material Science and Manufacturing for Strength

Komatsu uses advanced material science to create strong bucket teeth. They craft these teeth from high-grade alloy steel. This steel undergoes special manufacturing processes. These processes enhance the teeth’s strength and wear resistance. The KMAX Tooth System is a key example. It features a precise fit. This fit minimizes movement. It also ensures consistent performance. The KMAX system includes a hammerless locking mechanism. This mechanism allows quick and safe tooth replacement. It reduces downtime. It also extends replacement intervals by up to 30%. This means teeth last longer between changes.

GET System Design for Durability

Komatsu’s Ground Engaging Tools (GET) system design focuses on durability. It uses high-grade materials. These materials offer superior hardness, tensile strength, and yield strength. For example, T3 grade material provides 1.3 times the wear life of T2. This makes T3 ideal for extended wear applications. It directly contributes to enhanced durability.

| Material Grade | Hardness (HRC) | Tensile Strength (Mpa) | Yield Strength (N/mm2) | Wear Life Relative to Grade 2 |

|---|---|---|---|---|

| T1 | 47-52 | 1499 | 1040 | 2/3 |

| T2 | 48-52 | 1500 | 1100 | 1 (General Purpose) |

| T3 | 48-52 | 1550 | 1100 | 1.3 (Extended Wear) |

Komatsu also optimizes the design geometry of its GET system. Triangular, pointed tips are very effective. They penetrate hard rock and compact soil. These tips achieve 30% deeper penetration than flat-tipped designs. Self-sharpening profiles also help. They maintain digging efficiency as teeth wear. This reduces wear and extends durability.

| Feature | Specification | Benefit |

|---|---|---|

| Tip Design | Triangular, pointed tip | Efficiently penetrates hard rock and compact soil |

| Penetration | Triangular pointed tip (ASTM D750) | 30% deeper penetration than flat-tipped designs |

| Profile | Self-sharpening profiles | Maintains digging efficiency as teeth wear |

Komatsu’s GET system includes secure locking mechanisms. These mechanisms prevent teeth from detaching. This enhances durability and safety during demanding operations. Key systems include:

- Kprime system: This system features an intuitive locking system. It has an improved pin design. This design resists unlocking even after long use.

- Kmax system: This is a patented hammerless tooth system. It allows quicker and safer tooth changes.

- XS™ (Extreme Service) TS system: This is also a hammerless system. It uses a reusable fastener. This contributes to efficient maintenance and prolonged tooth life.

Performance in High-Impact Applications

Komatsu bucket teeth perform well in high-impact applications. Komatsu severe duty buckets use robust Komatsu bucket teeth. They are engineered for extreme applications. These applications involve hard, abrasive materials. Examples include rock and compacted soil. These buckets feature heavy-duty, replaceable bucket teeth. They also have reinforced cutting edges. These parts resist breakage and wear. This ensures efficient excavation in challenging environments. They are built with higher-grade steel. They also have additional reinforcement. This helps them withstand higher impact and prolonged wear. This is true compared to standard or heavy-duty buckets.

Komatsu bucket teeth for high-impact applications are vital. They are crucial for operations with high breakout forces. These include digging in hard, rocky, or quarry-based areas. Achieving optimal performance also requires a correct teeth-to-adapter partnership. This prevents premature breakages. Some tooth types are specifically designed for these conditions.

| Tooth Type | Penetration | Impact | Wear Life |

|---|---|---|---|

| Twin Tiger | High | High | Low |

| Single Tiger | High | High | Low |

| These tooth types offer high penetration and impact resistance. They are suitable for tough jobs. |

Direct Comparison: Caterpillar Bucket Teeth vs Komatsu in Scenarios

Abrasive Digging: Which Lasts Longer?

When digging in very abrasive materials, Caterpillar bucket teeth often show superior longevity. These materials include sand, gravel, or hard-packed clay. Caterpillar uses special alloys and heat treatments. These processes make their teeth very hard and resistant to wear. The design of Caterpillar teeth also helps. It spreads out the wear evenly. This means the teeth last longer before needing replacement. Komatsu teeth also offer good wear resistance. They use strong materials and smart designs. However, Caterpillar’s specific material science often gives it an edge in these extremely abrasive conditions.

High-Impact Applications: Which Lasts Longer?

High-impact jobs involve breaking tough materials. These include rock quarrying or demolition work. Both brands offer strong teeth for these tasks. In granite quarrying operations, Caterpillar bucket teeth show excellent impact resistance. They use high-manganese steel. Their bionic tooth profile design helps. The curved tooth surface spreads out contact stress. This stops stress from building up in one spot. It prevents the tip from breaking. The thickened tooth root can handle excavation impacts of 300 kN. This ensures steady work even with repeated hits.

For demolition work, operators often choose Esco bucket teeth. Esco uses special alloys with chromium and nickel. This makes them harder and tougher. They also have a special heat treatment. This creates a hard outer layer and a tough core. Esco teeth work very well in mining, quarrying, and demolition. Cat bucket teeth use high-strength alloy steel and heat treatment. This increases their hardness. Their design helps spread force evenly. This reduces the chance of chipping or cracking. However, Cat teeth might wear faster in very abrasive environments, which can include demolition. Komatsu teeth also perform well in high-impact situations. Their T3 grade material offers extended wear life. This makes them a strong choice for jobs with heavy impacts.

General Purpose Excavation: A Balanced View

For general excavation tasks, both Caterpillar and Komatsu offer reliable bucket teeth. These tasks include digging in common soil, dirt, or mixed ground. Both brands provide teeth that balance penetration, wear life, and impact resistance. The best choice often depends on the specific job site. It also depends on the operator’s preferences.

Komatsu’s self-sharpening profiles help maintain digging efficiency. This is useful in varied conditions. Caterpillar’s GET systems also focus on extended life and easy maintenance. For everyday digging, both brands offer durable options. The key is to match the tooth type to the exact work. This ensures maximum lifespan and efficiency.

Maximizing the Lifespan of Your Bucket Teeth

Proper Tooth Selection for the Job

Choosing the correct bucket teeth for a job greatly extends their life. Operators must match the tooth profile to the material they dig. For mixed materials, rock teeth work well. They offer durability, better penetration, and a longer lifespan. The material of the teeth also matters. Harder materials like alloy or manganese steel are best for tough jobs. Tungsten carbide teeth last two to three times longer in rocky or abrasive conditions.

| Bucket Teeth Type | Ground Conditions / Application |

|---|---|

| Standard | General earthmoving, moderate abrasive conditions |

| Rock | Rocky or frozen ground, withstands pounding hits |

| Heavy Duty | Very rough conditions, quarrying, mining, demolition, high resistance to abrasion and impact |

Regular Inspection and Replacement

Regular checks prevent early wear and damage. Operators should look for critical wear indicators. Replace teeth when they lose 40% of their original length. Also, replace them if the shank diameter wears, causing loose connections or bluntness. A tooth needs replacement when wear reaches an indicator mark. Ignoring these signs can lead to more damage to the bucket.

Operator Technique for Reduced Wear

Operator actions directly affect tooth wear. Maintain the bucket teeth perpendicular to the working surface. The outward inclination angle should not exceed 120 degrees. Exceeding this angle causes uneven force and breakage. Avoid swinging the digging arm left and right under heavy resistance. Most bucket teeth cannot handle excessive lateral forces. This can break both the teeth and their seats. Operators should also use the correct digging mode for the material. They must minimize unnecessary high-impact tasks.

The “longer lasting” brand between Caterpillar bucket teeth and Komatsu teeth depends on the specific application. Caterpillar bucket teeth often lead in highly abrasive environments. This is due to their material science. Komatsu teeth frequently demonstrate superior resilience in high-impact scenarios. The best choice for longevity is the tooth system optimized for your specific work. Diligent maintenance and proper operation are crucial for maximizing lifespan.

FAQ

Which brand is better for abrasive digging?

Caterpillar bucket teeth often last longer in abrasive conditions. Their special alloys and heat treatments provide superior wear resistance.

Which brand is better for high-impact work?

Komatsu teeth frequently show better resilience in high-impact situations. Their material science and design focus on strength for tough jobs.

How can I make my bucket teeth last longer?

Proper selection, regular inspection, and good operator technique extend lifespan. Match the tooth type to the job for best results.

Post time: Dec-02-2025