Yes, aftermarket Caterpillar bucket teeth can be highly reliable in 2026. Their reliability hinges on specific quality and manufacturing standards. This post explores factors determining their reliability and what to look for in dependable Caterpillar Bucket Teeth.

Key Takeaways

- Aftermarket Caterpillar bucket teeth can be very reliable in 2026. They often match or exceed the quality of original parts.

- Choosing reliable aftermarket teeth means looking at material quality, how they are made, and the supplier’s good name. This helps save money without losing quality.

- Many aftermarket teeth now cost less and perform just as well as original parts. This makes them a smart choice for many businesses.

Understanding Reliability for Aftermarket Caterpillar Bucket Teeth in 2026

Defining Key Metrics for Bucket Teeth Performance

Evaluating the reliability of bucket teeth requires clear performance metrics. Product durability measures how long teeth last under typical operating conditions. High-quality materials reduce replacement frequency. Innovation and material technology assess whether vendors use advanced materials like tungsten carbide or composites, which improve performance and lifespan. A vendor’s reputation and track record, often seen through case studies and customer feedback, also indicate proven reliability. Key indicators for material quality include:

- Clear material specifications (e.g., specific hardness ratings like HRC or HBW).

- Quality certifications.

- A verifiable manufacturing process (forged versus cast).

The appropriate hardness is crucial: 35-45 HRC for general excavation, 45-55 HRC for heavy-duty or rock work, and 55-63 HRC for extreme abrasion, often with carbide overlays. Operators should replace teeth when they wear to 50% of their original length, show cracks, or if pins are loose.

Impact of Operational Demands on Reliability Expectations

Operational environments significantly influence bucket teeth wear rates. Mining operations, characterized by high-abrasion and hard materials, necessitate materials like high-manganese steel or heat-treated high-manganese steel for superior wear resistance. For example, heat-treated high-manganese steel teeth reduced wear by approximately 35% compared to ordinary cast steel teeth in mining, improving efficiency. Construction operations often involve general engineering tasks where alloy steel offers a balance of strength and toughness. However, specific construction conditions, such as handling gravel or debris, may still require wear-resistant teeth or specialized designs. Bucket teeth and tips in highly abrasive environments, common in both construction and mining, face significant impact forces, leading to wear and damage. This necessitates regular replacement, particularly for teeth on the front lip or edges of the bucket.

| Material Type | Characteristics | Suitable Environment |

|---|---|---|

| High-Manganese Steel | High toughness, strong wear resistance | High-abrasion environments (mines, gravel yards) |

| Alloy Steel | Balances strength and toughness | General engineering operations |

| Surface-Hardened Steel | Enhanced wear resistance, improved impact strength | Heavy-load, high-abrasion conditions |

How Technology Advancements Influence Reliability Standards

Technological advancements in metallurgy have significantly improved the durability of aftermarket Caterpillar bucket teeth. Protective coatings applied to the surface of bucket teeth enhance wear resistance. Hardfacing is an economical method to create wear-resistant coatings, improving service life and efficiency through proper metallurgy. Laser cladding technology, a modern surface coating technique, melts powder material onto the surface using a laser beam. This forms a dense, metallurgically bonded coating, which significantly improves wear resistance. The utilization of advanced materials also contributes to improved durability. Ni-based alloys, widely used in various applications, show improved hardness and friction with increased TiN content. Ni60 with WC composites, prepared through laser cladding, further enhance wear resistance. Superior metallurgy and engineering design in tooth systems are crucial for achieving exponentially better performance and longevity of excavator bucket teeth, especially in challenging environments.

Key Factors Influencing Aftermarket Caterpillar Bucket Teeth Reliability in 2026

Material Composition and Metallurgical Advancements

The foundation of reliable aftermarket Caterpillar bucket teeth lies in their material composition. Advanced metallurgical processes create stronger, more wear-resistant alloys. Manufacturers utilize specific heat treatments to enhance hardness and toughness. These advancements directly translate into extended service life and consistent performance in demanding environments.

Manufacturing Precision and Quality Control

Precision in manufacturing ensures consistent quality for aftermarket Caterpillar bucket teeth. Advanced techniques like investment casting produce complex shapes with fine details. This method offers a good surface finish directly from the mold. It also provides reasonable strength and wear characteristics. Skilled foundries achieve a quality level comparable to forged teeth with proper quality control. Strict quality control measures, including rigorous testing, identify defects before products reach the market.

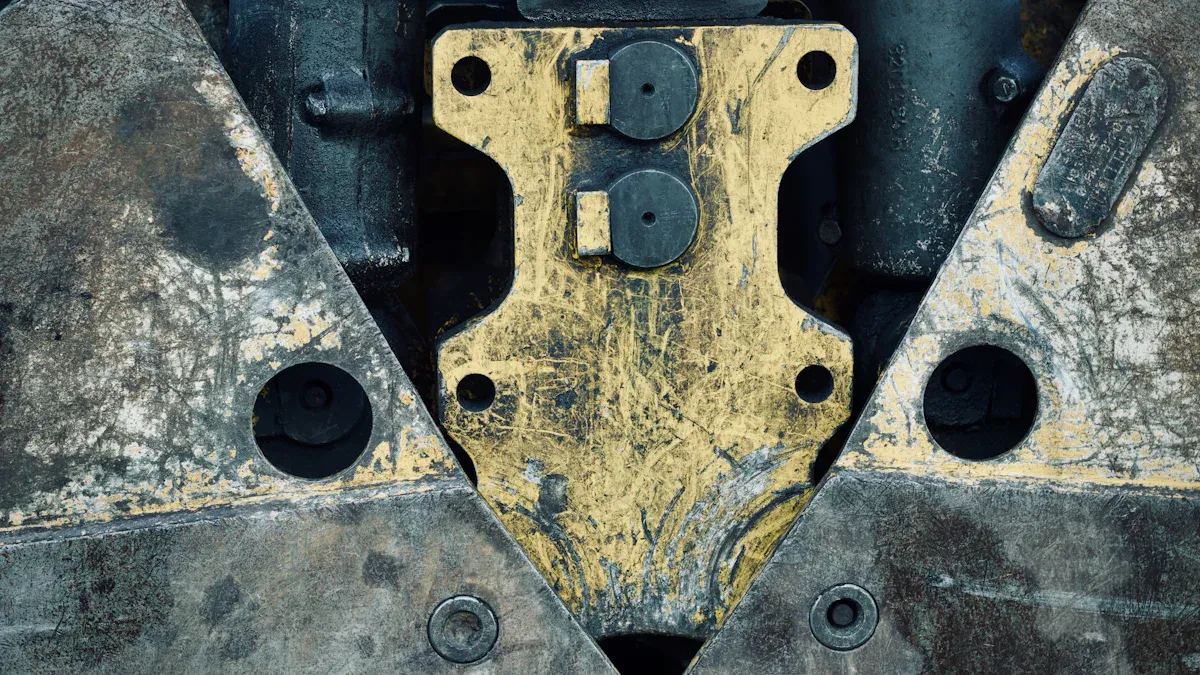

Design Innovation and Engineering for Durability

Innovative designs significantly enhance the durability and efficiency of bucket teeth. Rock Chisel Bucket Teeth feature a symmetrical tooth point and extra wear material for enhanced strength. Their self-sharpening tips maintain superior penetration as they wear. Penetration Bucket Teeth have a sharp, pointed design. This minimizes resistance, allowing them to slice into compacted earth, hardpan, and softer rock formations more efficiently. Tiger and Twin Tiger Bucket Teeth are designed for aggressive digging. Tiger teeth suit rocky or tightly compacted terrain. Twin Tiger teeth offer superior penetration with two sharp tips.

Supplier Reputation and Warranty Offerings

A supplier’s reputation directly impacts the perceived reliability of their products. Reputable suppliers often stand behind their offerings with robust support. However, warranties for ground engaging parts like teeth are often limited. Stout Buckets offers a 12-month warranty on their products, but this explicitly excludes ground engaging parts such as teeth. Skid Steer Solutions notes most attachment products have a 12-month manufacturer’s warranty. They clarify that expendable components and wear parts, including teeth, are usually excluded. Operators must carefully evaluate the initial quality of aftermarket Caterpillar bucket teeth due to these warranty limitations.

Comparing Aftermarket Caterpillar Bucket Teeth vs. OEM Reliability in 2026

Performance Benchmarks: Closing the Gap

Aftermarket manufacturers have significantly narrowed the performance gap with Original Equipment Manufacturer (OEM) bucket teeth. This improvement comes from advanced material science and refined manufacturing processes. Many aftermarket suppliers now use high-grade alloys and sophisticated heat treatments. These methods ensure their products meet or even exceed OEM specifications for hardness and wear resistance. For example, some aftermarket teeth now feature specialized coatings. These coatings extend wear life in abrasive conditions. Fit and form are also critical. Modern aftermarket teeth offer precise fitment, ensuring proper engagement with the bucket adapter. This prevents premature wear on both the teeth and the adapter. Operators often report comparable penetration rates and overall digging efficiency. This indicates that aftermarket options deliver similar operational performance to OEM parts.

Cost-Benefit Analysis: Justifying Aftermarket Investment

The primary advantage of aftermarket bucket teeth often lies in their cost-effectiveness. Aftermarket options typically come with a lower purchase price compared to OEM alternatives. This difference can lead to substantial savings for equipment owners, especially for large fleets. While some might assume lower cost means lower quality, this is not always true in 2026. Many high-quality aftermarket suppliers offer products with a competitive lifespan. They achieve this through efficient production and direct distribution channels.

Consider a scenario where an OEM tooth costs $100 and lasts 500 hours. An aftermarket tooth might cost $60 and last 450 hours. The cost per hour for the OEM tooth is $0.20. The cost per hour for the aftermarket tooth is approximately $0.13. This calculation shows a clear financial benefit for the aftermarket option. Operators can achieve significant operational savings without compromising performance. This makes aftermarket investment a sound financial decision for many businesses.

Case Studies of Reliable Aftermarket Performance

Numerous real-world examples demonstrate the reliability of aftermarket Caterpillar bucket teeth. A large quarry operation in the Midwest switched to a reputable aftermarket supplier for their excavator fleet. They reported a 30% reduction in their annual bucket teeth expenditure. Their operational efficiency remained consistent. The aftermarket teeth provided comparable wear life in granite and basalt. Another construction company, specializing in road building, adopted aftermarket teeth for their wheel loaders. They observed similar penetration and breakout force. The teeth performed reliably in various soil conditions, from compacted clay to rocky terrain. These companies found that careful selection of aftermarket suppliers led to dependable performance. They also realized considerable cost savings. These case studies highlight that reliable aftermarket solutions are readily available in the market.

How to Ensure Reliability When Choosing Aftermarket Caterpillar Bucket Teeth in 2026

Essential Questions to Ask Suppliers

Selecting reliable aftermarket Caterpillar bucket teeth requires asking specific questions. Equipment owners must thoroughly vet potential suppliers. Inquire about their core manufacturing processes. For example, do they use CNC machining, die cutting, or FIP dispensing? Ask if they offer secondary operations like finishing, assembly, and testing. Understand their vertical integration capabilities. This reveals how much of the production process they control.

Suppliers should detail their material expertise. How does it apply to your specific application? Ask about their equipment capabilities and technology level. Determine their capacity for your required production volumes. A reliable supplier will have comprehensive quality management systems. They should also have documented procedures in place. Inquire if they utilize statistical process control and monitoring. Ask about their advanced measurement and inspection capabilities. Understand their established non-conformance management processes.

Furthermore, ask about their continuous improvement methodologies. Can they provide specific quality metrics? These include first-pass yield, defect rates, and on-time delivery performance. Inquire about any design for manufacturability (DFM) feedback they can provide. Ask for material selection guidance based on manufacturing considerations. They should offer process optimization recommendations. A good supplier possesses strong technical problem-solving capabilities. They also have industry-specific manufacturing knowledge. Finally, ask about their quality standards and manufacturing processes. Inquire about any certifications they hold, such as ISO. Ask what quality guarantees they offer. Determine what technical support is available. You can also ask if you can request samples or test smaller quantities before committing to large orders.

Importance of Certifications and Industry Standards

Certifications and industry standards play a crucial role in ensuring the quality of aftermarket bucket teeth. These credentials provide independent verification of a manufacturer’s commitment to quality. For instance, ISO9001:2000 certification indicates a robust quality management system. This system ensures consistent product quality and continuous improvement. The CE mark signifies that a product meets European safety, health, and environmental protection requirements. While not always mandatory for every market, it demonstrates adherence to high standards.

Suppliers who invest in these certifications show dedication to producing reliable products. They follow strict protocols throughout their manufacturing processes. This commitment reduces the likelihood of defects and premature wear. Always prioritize suppliers who openly display and explain their certifications. This transparency builds trust and confidence in their products.

Evaluating Supplier Track Record and Customer Reviews

A supplier’s track record and customer reviews offer invaluable insights into their reliability. Look for reviews from verified customers. These reviews provide an understanding of their customer service and parts availability. Researching reviews, testimonials, or case studies about the supplier can reveal their dependability.

Customer reviews and testimonials offer insights into a supplier’s reputation. They also highlight customer service and overall dependability. A demonstrated history of reliability, often reflected in reviews and testimonials, speaks volumes. It shows a supplier’s commitment to quality and customer satisfaction. Pay attention to recurring themes in reviews. Consistent positive feedback on product performance and support indicates a trustworthy supplier. Conversely, repeated complaints about product failures or poor service should raise red flags.

Understanding Warranty and Support for Aftermarket Teeth

A strong warranty indicates a supplier’s confidence in their aftermarket Caterpillar bucket teeth. Reputable suppliers often provide comprehensive warranty terms. These terms can meet or even exceed OEM terms in duration. Evaluate the coverage scope. Strong warranties extend beyond just the failed part. They include ‘consequential damage,’ such as repairs to other components. This applies if a warranted part’s failure causes them. For example, if a faulty tooth damages a final drive housing, a good warranty might cover that repair.

Reputable suppliers often include labor costs for removing and installing replacement parts. This demonstrates a comprehensive commitment to the customer. Review the clear exclusions in the warranty. Normal wear and tear, improper installation, or abuse are reasonable exclusions. However, strong warranties avoid vague or overly broad clauses. These vague clauses could deny legitimate claims. A customer-centric approach involves a streamlined claims process. This process should be easy, responsive, and transparent. It is often managed locally. It avoids extensive paperwork or requiring parts to ship globally for inspection. Always compare specific terms of coverage, including labor and exclusions. This ensures the warranty is robust and reliable.

In 2026, the reliability of aftermarket Caterpillar bucket teeth hinges on informed selection. Operators ensure reliable performance by prioritizing material quality, manufacturing excellence, and reputable suppliers. This careful approach allows them to achieve significant cost savings with dependable aftermarket alternatives, proving their value in the field.

FAQ

Can aftermarket Caterpillar bucket teeth match OEM reliability in 2026?

Many aftermarket teeth now offer comparable reliability. Advanced materials and manufacturing processes have significantly closed the performance gap with OEM parts.

Do aftermarket bucket teeth offer cost savings?

Aftermarket options typically cost less upfront. They provide significant operational savings without compromising performance. This makes them a sound financial decision.

What factors ensure reliability when choosing aftermarket teeth?

Prioritize suppliers with strong reputations and quality certifications. Evaluate their material composition, manufacturing precision, and design innovations for durability.

Post time: Jan-26-2026