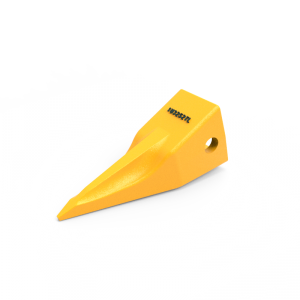

4T1204 Caterpillar J200 Replacement Excavator Weld-On Bucket Tooth Adapter

Specification

Part No.: 4T1204/4T-1204

Weight: 2KG

Brand: Caterpillar

Series: J200

Material: High Standard Alloy Steel

Process: Investment Casting/Lost Wax Casting/Sand Casting/Forging

Tensile Strength: ≥1400RM-N/MM²

Shock: ≥20J

Hardness: 48-52HRC

Color: Yellow, Red, Black, Green or Customer's Request

Logo: Customer's Request

Package: Plywood Cases

Certification: ISO9001:2008

Delivery Time: 30-40 days for one container

Payment: T/T or can be negotiated

Place of Origin: Zhejiang, China(Mainland)

Product Description

4T1204 Caterpillar J200 Replacement Excavator Flush Mount Weld-On Bucket Adapter, J200 Weld-On Loader Bucket Tooth Tip Adapters, Aftermarket Replacement Wheel Loader Bucket Teeth Holder Shank System, CAT J Series Central Two Strap Adapter Fits Caterpillar Digging Tooth, G.E.T. Spare Parts China Leading Supplier

The tooth is directly fit for Caterpillar J200 Series Tooth, takes pressure off the machine and bucket helping improve performance&lifespan.

Caterpillar Bucket Teeth are made of casting alloy steel and can be used on various models of caterpillar excavators.

Caterpillar style flush mount loader adapter for a J200 series with a 1/2”-1”lip thickness.

J200 series spare parts can be used in machinery Caterpillar Backhoe Loader 416C, Integrated Tool Carrier IT12B, Backhoe Loader 416D, Integrated Tool Carrier IT14G, Backhoe Loader 420D ....

We have standard types and customized products as per customers' requests.

Our goods are made using high-quality raw materials and have high standards for performance, abrasion resistance, and durability.

We offer a full range of wear spare parts for bucket teeth, adapters, cutting edges, protectors, shanks and pins& retainers, bolts&nuts to match as a professional G.E.T. supplier.

Direct replacement parts for leading brands(such as Caterpillar, Doosan, Komatsu, Hitachi, Volvo, JCB etc) are provided and used for both construction sector and mining sector.

Welcome your inquiries if have any interested types!

Hot-selling

| Hot-Selling Products: | |||

|

Brand |

Series |

Part No. |

KG |

|

Caterpillar |

J200 |

4T1204 |

2 |

|

Caterpillar |

J220 |

6Y3222 |

2.1 |

|

Caterpillar |

J250 |

1U3251 |

2.4 |

|

Caterpillar |

J300 |

1U3301 |

3.8 |

|

Caterpillar |

J350 |

1U3351 |

5.4 |

|

Caterpillar |

J400 |

7T3402 |

9.5 |

|

Caterpillar |

J460 |

9W8451 |

10.2 |

|

Caterpillar |

J550 |

9W8551 |

15 |

|

Caterpillar |

J600 |

9W8552 |

17.5 |

|

Caterpillar |

J700 |

4T4703 |

50 |

Inspection

production

live show

Frequently Asked Questions

Q: What is the delivery time?

A: For lost-wax casting process, it takes 20 days roughly from the fisrt step till the bucket teeth finished. So if you order, it takes 30-40 days, beacuse we have to wait for production and other items.

Q: What is the heat treatment equipment for the bucket teeth and adapters?

A: For different size and weight, we use different heat treatment equipment, small ones which means weight less than 10 kgs, heat treatment in mesh belt furnace, if over 10 kgs it will be tunnel furnace.

Q: How to make sure the mining bucket teeth not break?

A: Special material: our material is same as BYG material composition, 2 times of heat treatment process, heavy design on the pocket. ultrasonic flaw detection will be done one by one.

Q: Which market we are specialisted?

A: Our bucket wear parts sale to all over the world, our main market is Europe, South American and Australia.

Q: How to make sure delivery intime as order?

A: Sales department, Order Tracking Department, production department working together to make sure all is under control, we have meeting to check the schedule every Monday afternoon.

Q: Our production process

A: All our bucket tooth and adapter are produced by lost - wax process, the best performance.