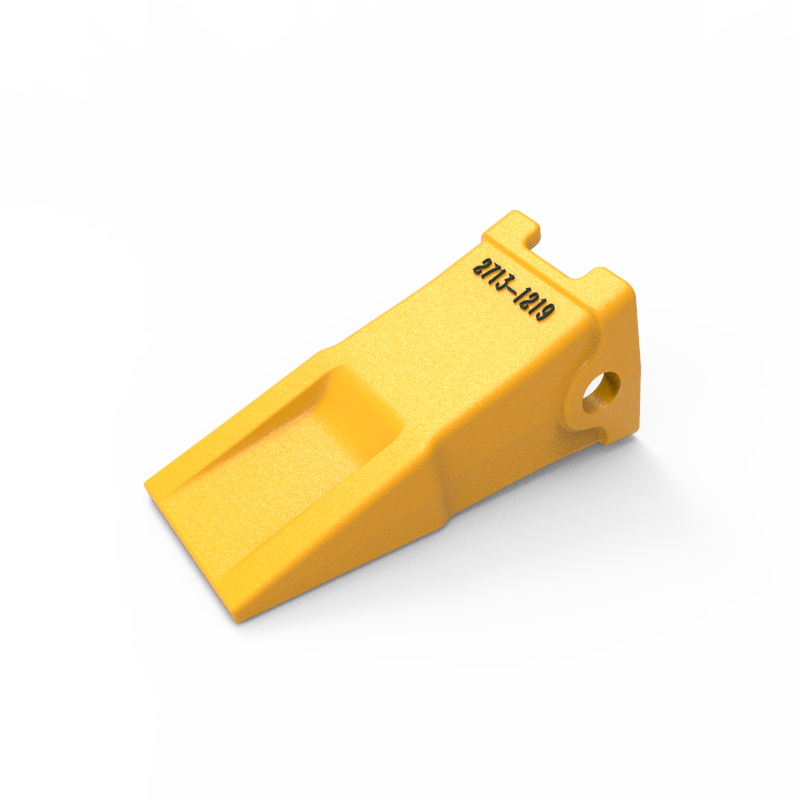

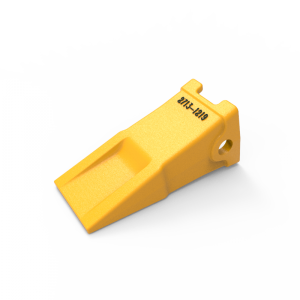

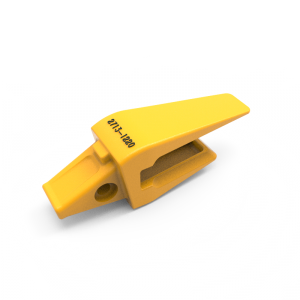

2713-1219 Doosan DH280 Replacement Daewoo Excavator Loader Standard Bucket Tooth

Specification

Part No.: 2713-1219/2713Y1219/2713-1270/2713Y1270

Weight: 7KG

Brand: Doosan/Daewoo

Series: DH280

Material: High Standard Alloy Steel

Process: Investment Casting/Lost Wax Casting/Sand Casting/Forging

Tensile Strength: ≥1400RM-N/MM²

Shock: ≥20J

Hardness: 48-52HRC

Color: Yellow, Red, Black, Green or Customer's Request

Logo: Customer's Request

Package: Plywood Cases

Certification: ISO9001:2008

Delivery Time: 30-40 days for one container

Payment: T/T or can be negotiated

Place of Origin: Zhejiang, China(Mainland)

Product Description

2713-1219 Doosan DH280 Alternative Standard Bucket Tooth for Daewoo Excavator Loader, DH300 Replacement Side Tips Tooth Point for Doosan Excavators , Adapter and Digging Teeth for Doosan/Daewoo Digger, China Supplier of G.E.T. Wear Spare Parts Bucket Teeth, Aftermarket OEM Doosan Style Bucket Teeth.

Daewoo style dirt bucket teeth for model DH280/DH300 , takes a 9J2358 pin and 8E6359 sleeved retainer .

We have a full selection of wear components for bucket teeth, adapters, cutting edges, pins and retainers, bolts and nuts, and more as a leading manufacturer of G.E.T. parts.

In accordance with customer requests, we offer both standard types and customized items.

Our goods are made using high-quality raw materials and have outstanding abrasion resistance, performance, and durability.

Professional personnel thoroughly inspect each step of the process, from casting to heat treatment, to assure high quality.

Excavators, loaders, bulldozers, graders, and scarifies may all be utilized direct replacement parts for top brands like Caterpillar, Komatsu, Hitachi, Doosan, Volvo, JCB, Hyundai, etc.

We supply quality products with fashionable designs and professional services. Our goal is to achieve win-win benefits cooperation and expand business opportunities for both of us ! If you have any questions or need more information, please feel free to contact us. We are looking forward to receiving your inquiries !

Hot-Selling

|

Brand |

Series |

Part No. |

KG |

|

Doosan/Daewoo |

DH140 |

2713-1221 |

4.1 |

|

Doosan/Daewoo |

DH220 |

2713-1217 |

5 |

|

Doosan/Daewoo |

DH300 |

2713-1219 |

7.5 |

|

Doosan/Daewoo |

DH360 |

713-00032 |

9.1 |

|

Doosan/Daewoo |

DH500 |

2713-1236 |

15.5 |

|

Doosan/Daewoo |

DH500 |

2713-1237(55) |

23.1 |

Inspection

production

live show

Frequently Asked Questions

Q: What is the delivery time?

A: For lost-wax casting process, it takes 20 days roughly from the fisrt step till the bucket teeth finished. So if you order, it takes 30-40 days, beacuse we have to wait for production and other items.

Q: What is the heat treatment equipment for the bucket teeth and adapters?

A: For different size and weight, we use different heat treatment equipment, small ones which means weight less than 10 kgs, heat treatment in mesh belt furnace, if over 10 kgs it will be tunnel furnace.

Q: How to make sure the mining bucket teeth not break?

A: Special material: our material is same as BYG material composition, 2 times of heat treatment process, heavy design on the pocket. ultrasonic flaw detection will be done one by one.

Q: Which market we are specialisted?

A: Our bucket wear parts sale to all over the world, our main market is Europe, South American and Australia.

Q: How to make sure delivery intime as order?

A: Sales department, Order Tracking Department, production department working together to make sure all is under control, we have meeting to check the schedule every Monday afternoon.

Q: Our production process

A: All our bucket tooth and adapter are produced by lost - wax process, the best performance.